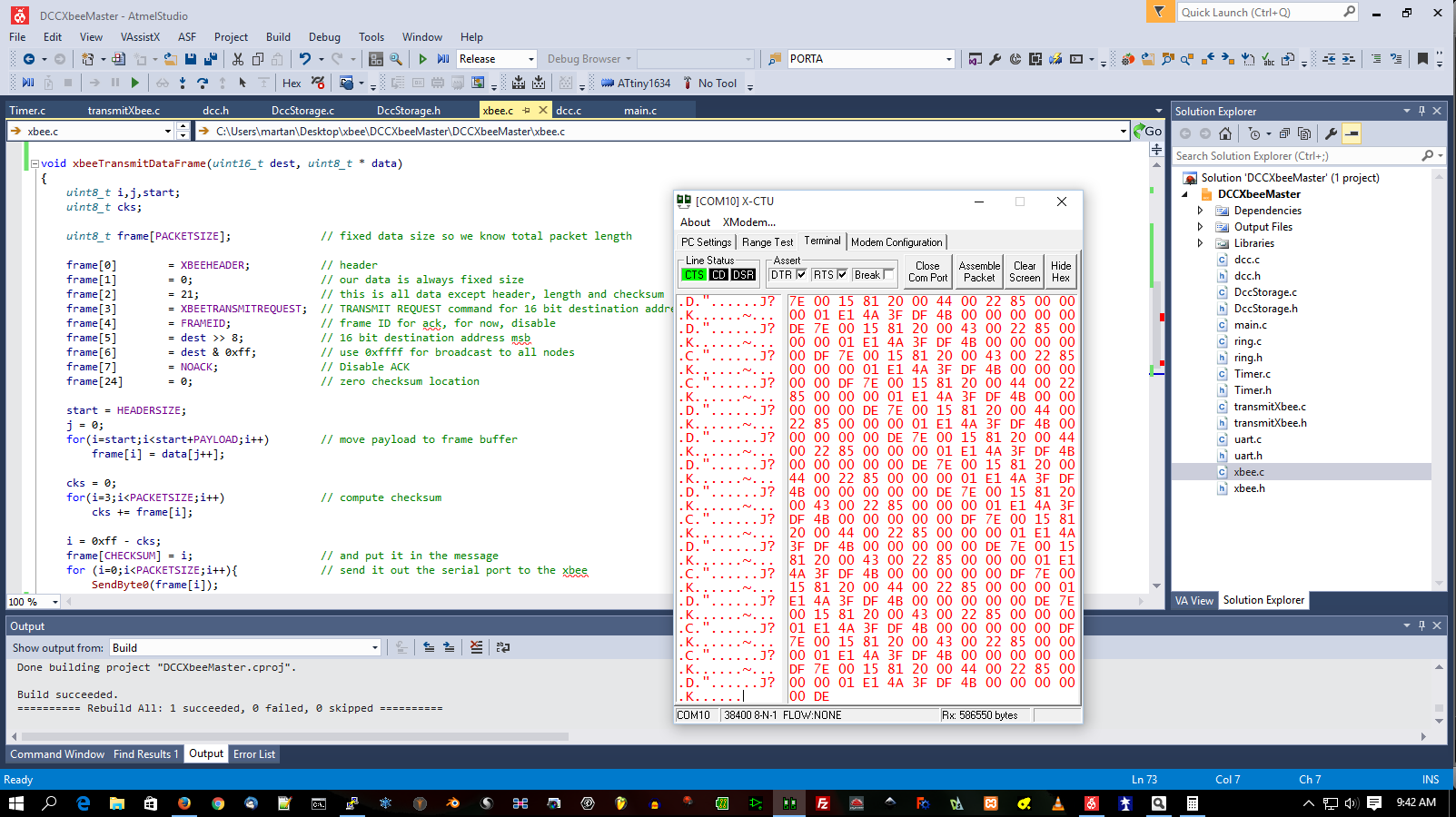

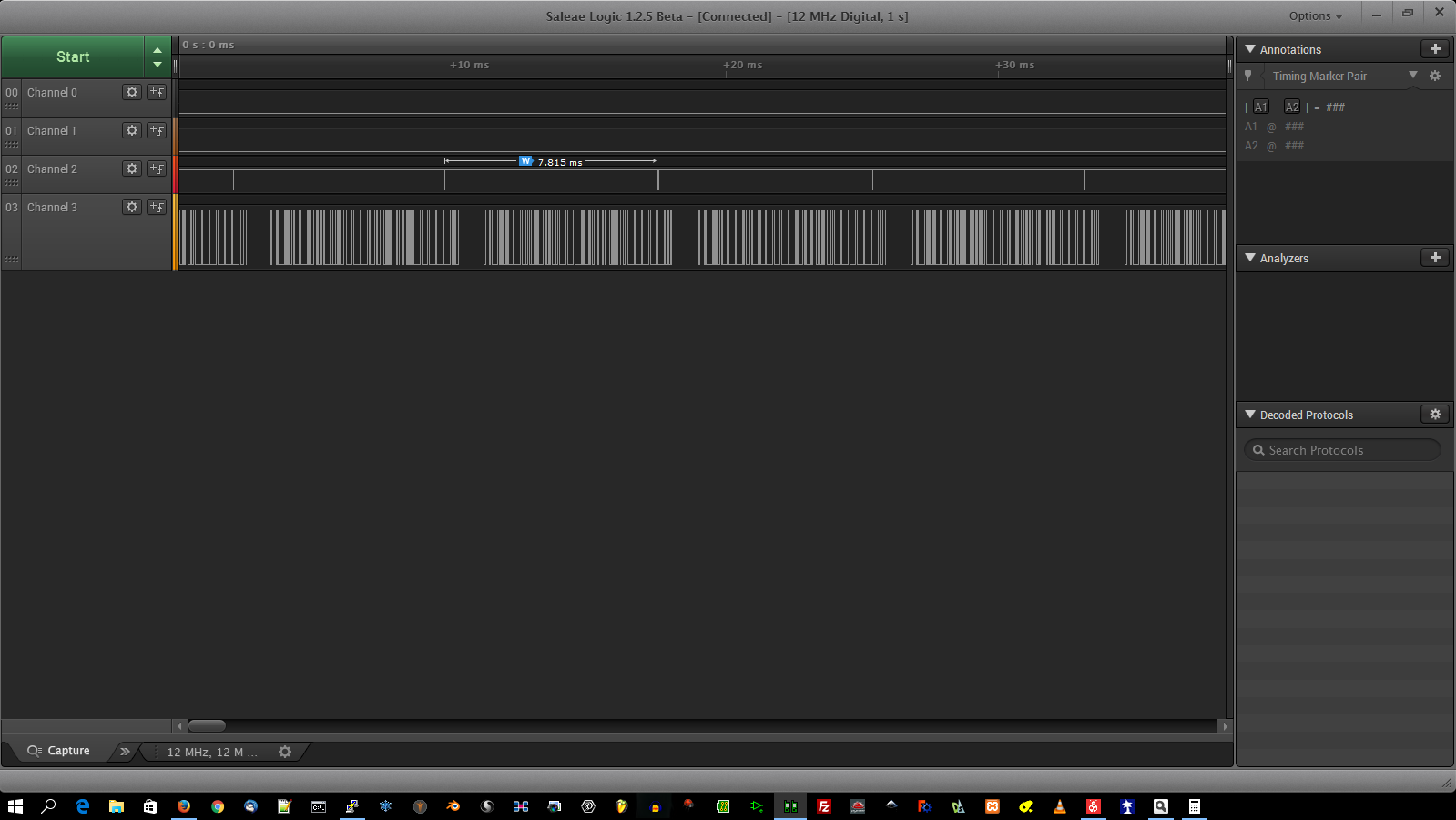

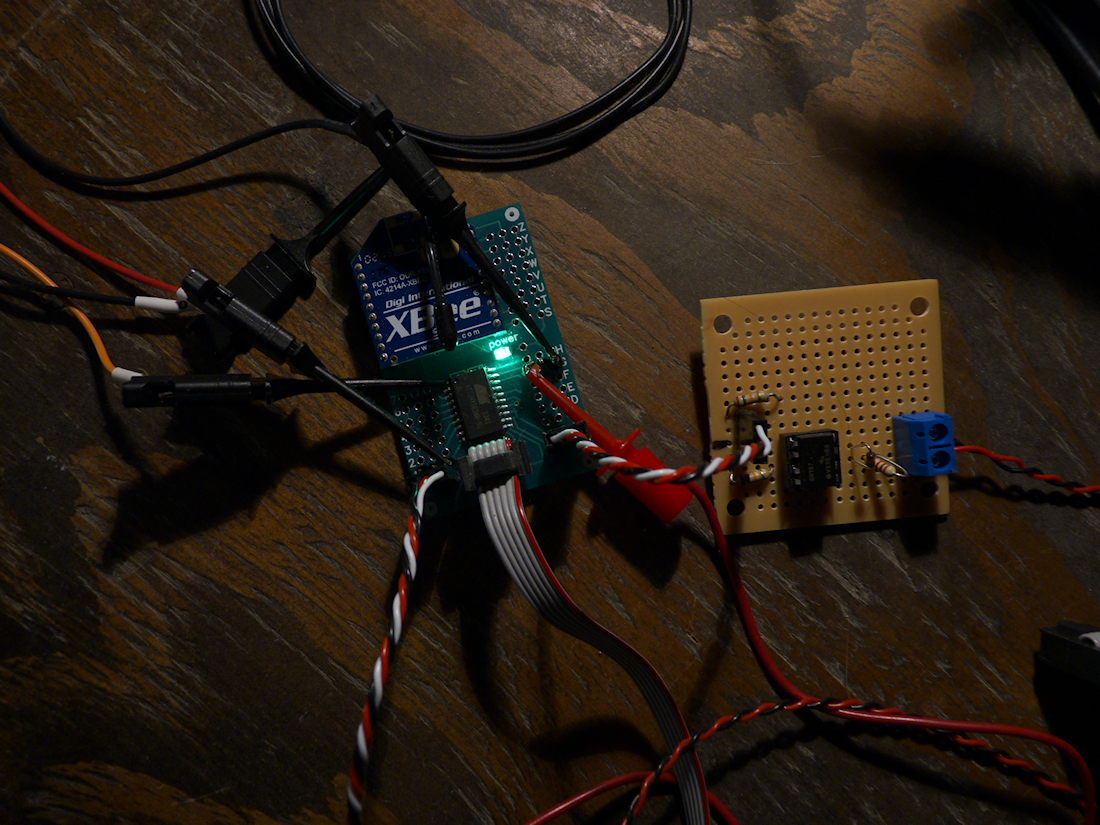

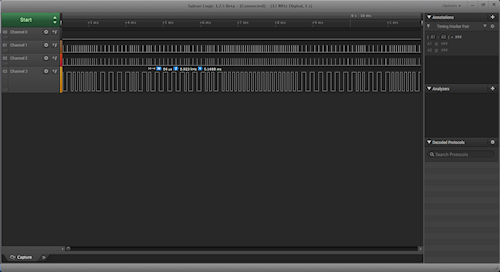

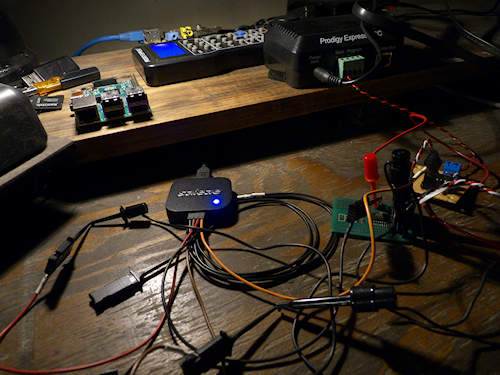

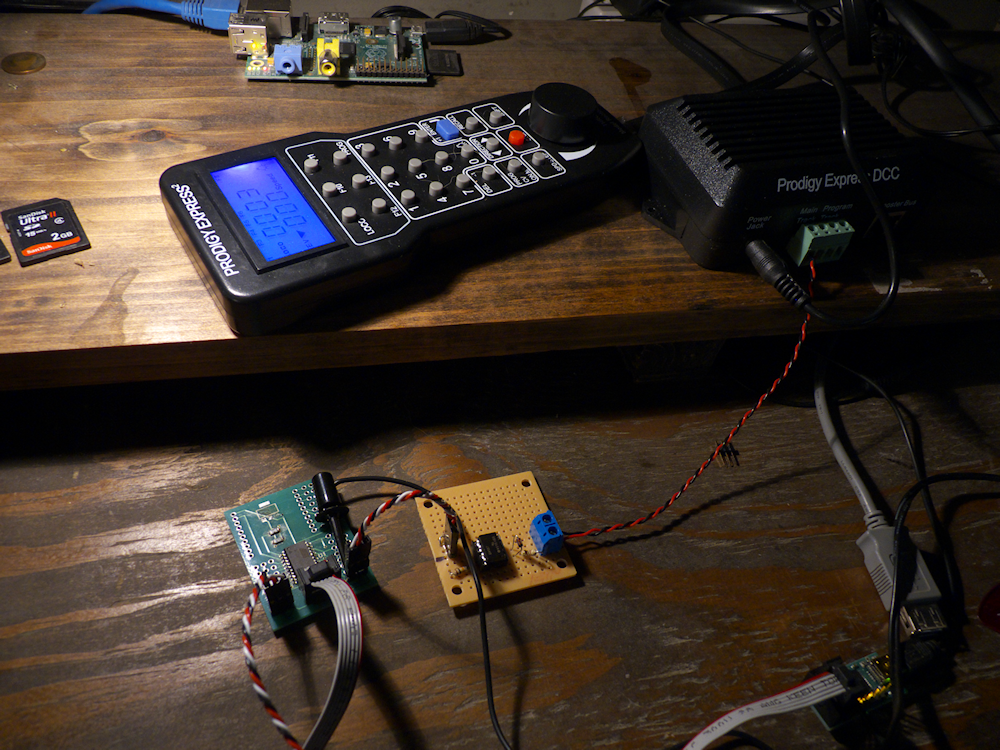

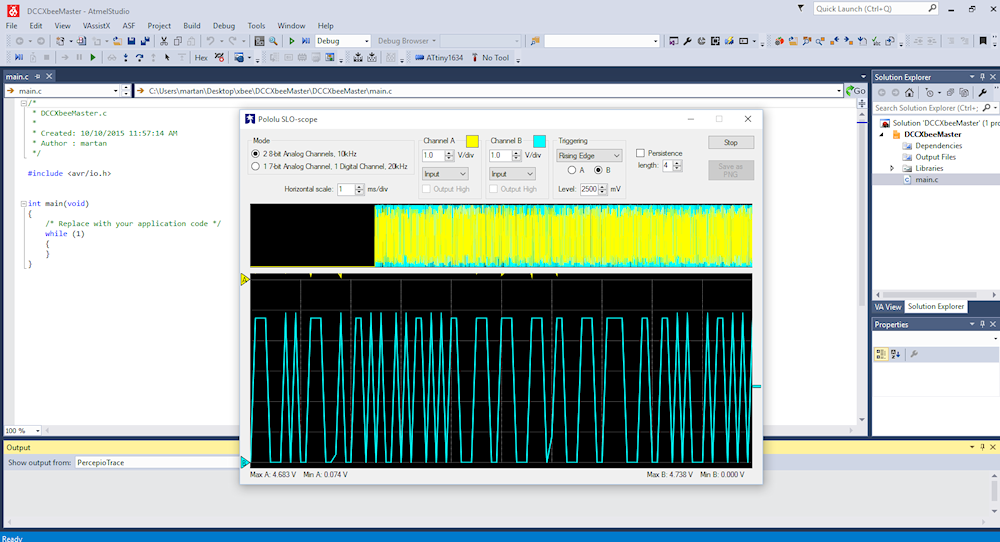

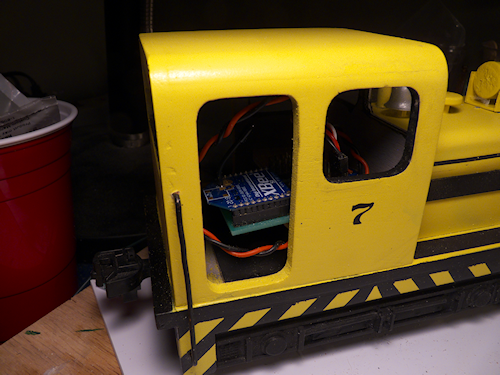

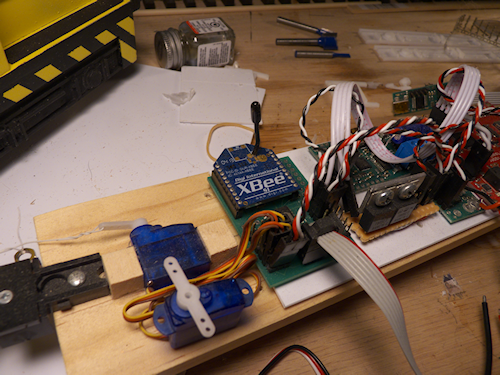

Here is the Prodigy DCC controlling a servo over my Xbee network. (the video is sped up 200%) This validates the network layer and the speed. However, this is just a raw implementation of the protocol. The DCC message is just sent as fast as possible, regardless if it has changed or not. I don’t want to keep it this fast, there are far far too many Xbee packets flying around. It is ‘thinned’ out a bit because only packets meant for address 8522 are sent to this Xbee but I will need to implement the proper algorithms so that only data that changes is on the network. The client can then maintain the DCC stream on it’s own. Also, with only 128 steps of speed control the precision is lacking controlling the servos smoothly. I’ll need to do some processing of the speed before it’s sent to the servos.

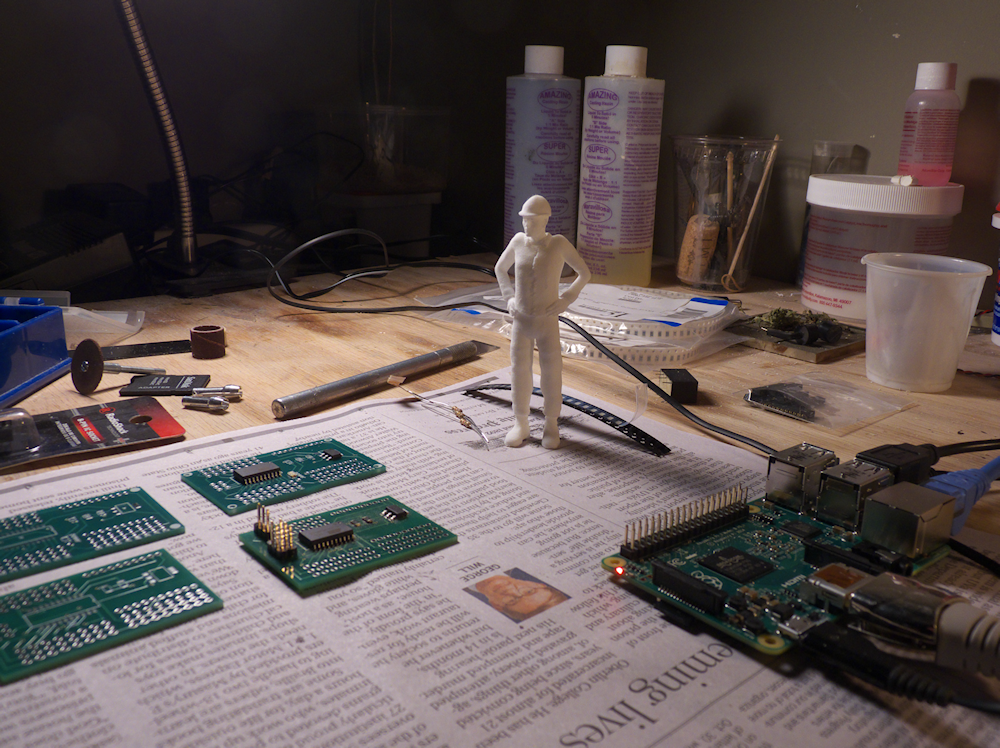

It has a ways to go before it’s a bonafide ‘wireless decoder’ but the basic wireless network works, and that’s the most important, everything else is just more firmware 🙂

So far, I’ve used less about a third of the flash and ram:

Program Memory Usage : 4908 bytes 30.0 % Full

Data Memory Usage : 215 bytes 21.0 % Full