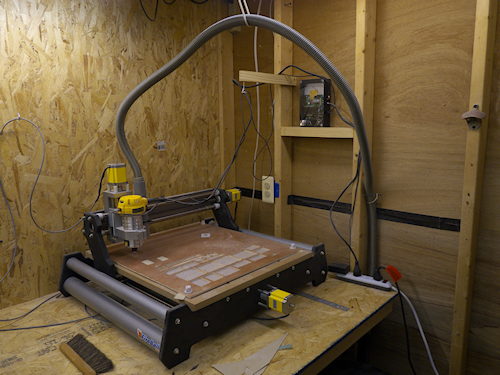

Working on another critter. I plan on three, with a base price of $26 for the kit or $6 for the digital download of the plans- for those who wish to cut them on their own CNC or laser machine.

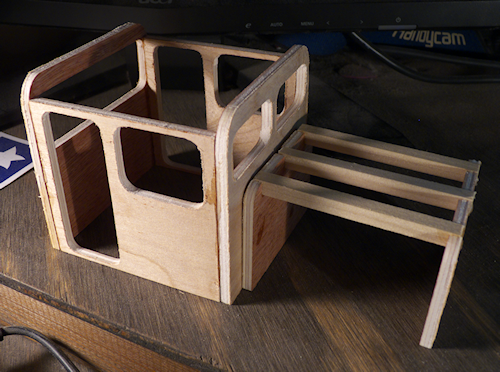

One of my 3D printed 1/29 scale fellows on a CNC cut out Critter. Its a tiny locomotive I’ve designed based on a collage of prototypes from google searches. It’s cut out of sheet of 5mm finish ply and fits on a USA Trains 4 wheel power truck. I’ve left room for batteries and controls, I’m not a track power guy.

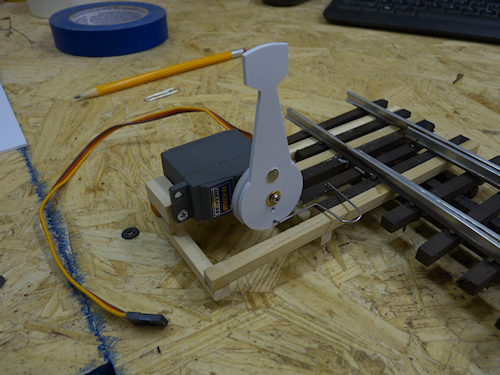

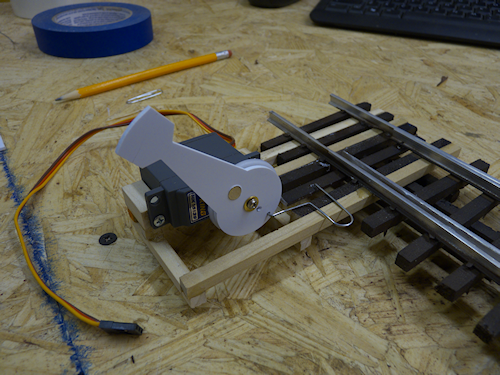

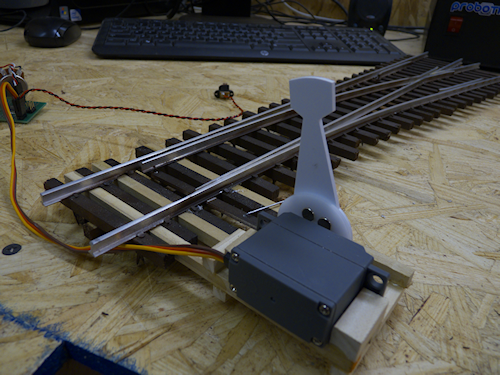

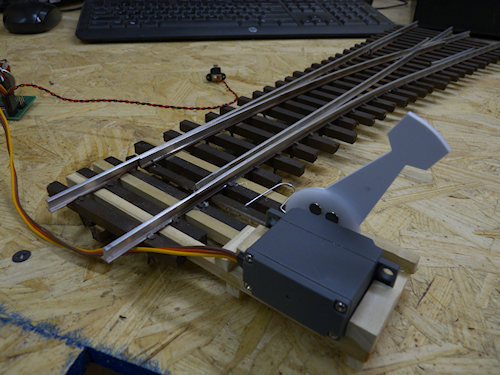

Here are some pictures of my computer/manual switch throw. I was looking for a device that I could use to throw a switch both with a manual lever and also have a servo drive it for computer control. This is what I came up with. After a bit of testing, it seems like it will do just what I want. It uses a cheap waterproof servo, three magnets and a styrene throw. There are two magnets on the servo wheel and one on the throw. There is no connection between the servo wheel and the actuator other than the magnetic ‘clutch’. The ‘spring’ wire is a paper clip bent to fit. With the servo off or centered, you can throw the switch manually and it ‘clicks’ to one of the two magnets on the wheel. Under computer control, the servo can rotate to ‘pick up’ the magnet on the arm to throw the switch. Works quite well on the bench so I’ll be installing it soon to test out in Gilbert.

Two of my favorite 3D folks printed from Shapeways in 1:20 scale. At this size you get some great detail in the cheapest print medium. They are still pricey but what can you do? I’m working on molds for resin casts but they are an art form themselves. Raspberry Pi in the background, pencil in the foreground for size.

They are here:

http://www.shapeways.com/shops/blueridgeengineering

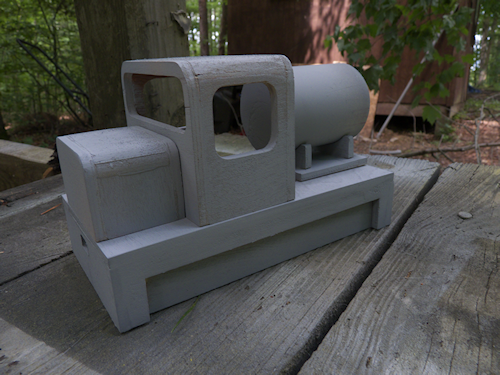

Finally got the basics together with a coat of primer. Some 1/29 People standing in front. Need some glass in the windows and an interior, some shingles on the roof and other details but the basic shell is coming off the router pretty well now. Still needs some tweaking to get a good solid production run but it’s coming together nicely.