Here are the steps I use to build a G Scale Turnout. This is a process that is going to take some time, so be prepared for that. I typically spend a week or three working part time on one so you have to like to make this sort of thing. Also, for best results, you are going to have to make a Jig to build them on. I built my first one on a piece of foam so you can do it that way but I don’t recommend it. You will also need a bench grinder. This really is a must-have tool to grind the points. They are not expensive, I think I got mine for $35 at Lowes. Other tools required are a set of sturdy needle nose pliers, lineman/electrical pliers, a hammer and a small file or two.

Before you start any of that stuff though, you need to make a set of plans that are EXACTLY the size of the turnout.

To find the plans, go here: handlaidtrack.com

You can download scale pdfs of various turnouts, crossings and other track stuff. By sizing that up by 280%, you get G scale turnout plans.

Here is how I have gotten it to work. First, you need to download a free drawing program called InkScape. You can find it here: http://www.inkscape.org/en/ (This is a great program that I also use to make my CNC cuts for my model houses and other buildings, but I digress) You use this program to resize the plan you downloaded.

You will also need another program to chop up the finished file into letter page sized printable ‘parts’. It’s called ‘posterrazor’ and you can get it HERE.

Once you have these installed, open inkscape and choose ‘import’ from the file menu. Find your pdf (that you downloaded from handlaidtrack.com) and select that to import. Takes a bit, InkScape isn’t a speed demon.

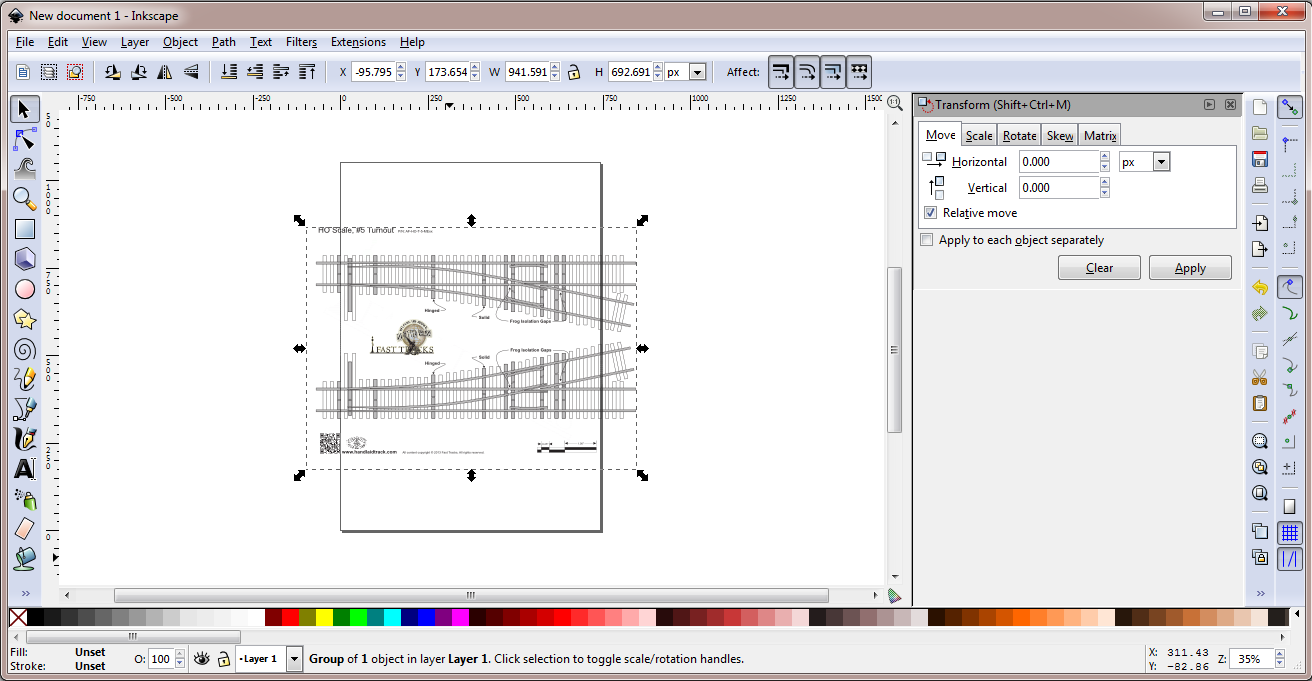

Once it’s imported, go to Object->Transform. It should look like this:

Click on the ‘scale’ tab at the top of the window to the right and then click ‘scale proportionally’. Change the width and height to 280 percent (It should be 300 strictly speaking but I’ve found that’s off just a bit so I use 280 instead). Click ‘Apply’ and the image will be resized. At this point, click the little selection on the right that has a percent in it (%) and change it to px so you know the dimensions of the image.

Now go to the file menu again and this time choose ‘export bitmap’. In the ‘Bitmap size’ area, enter the sizes from the step above. Choose an appropriate destination and file name and click ‘export’. I always use the ‘png’ format although I assume bmp would work as well.

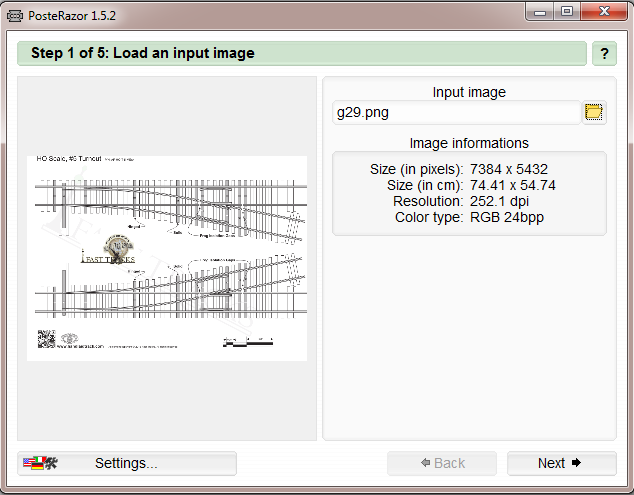

Now open up the other program ‘posterrazor’. Load the png you exported in the above step into posterrazor. It should look like this:

Click next and select ‘letter’ for the paper size and ‘landscape’ for the orientation. Click ‘next’ and just take the defaults presented there. Click ‘next’ again and select ‘size in percent’ and make sure that is set to 100% This should show you an image of how the large image will be broken up into several (many!) sheets of standard printer paper. Click next again and then click the little button under ‘save the poster’ This will create a new PDF sectioned off into the pages you need to print and then tape together to get a complete, full sized plan.

Note that for some of the pdfs on the handlaidtrack site, they are broken up into sheets already. You will have to load each of these sheets into inkscape and process each one like this to get a complete plan.

Also, I just print ONE page to test to make sure that the gauge is correct before I print out the whole thing. I use a short little piece of commercial G scale track to check and make sure the printed out drawing exactly matches. This is really important, if it’s off you can build a turnout that you can’t fix. (Ask me how I know this)

THE JIG

While you can build a turnout on a piece of foam, I’ve done it once, It’s far better to make a jig. I built my two jigs, one left and one right, on a piece of 10″ pine board. I take my printed out plan from the previous step and using contact spray glue, paste a copy on both sides of the board. One side I’ll use to actually build the turnout and the other is used to measure and bend the curved parts of the switch and the points. I use two pieces of aluminum angle on the side I build on. One is up against the ties on the straight side, the other is there so when you flip the jig over, (to size the rails and points) it rests evenly on the bench.

For the spacers on the jig, be sure they are not too tight, you want a fairly loose fit so you can get the completed switch out of the rig. Once the removed, you will want to glue some reinforcement strips to the bottom, be sure to water proof these too. The ballast should obscure these but they are important to give the turnout rigidity.

Tools

To actually build the turnout you will need a couple of tools – most importantly, you will need a bench grinder. These can be had at Lowes or Home Depot for about $40-$50. You will need this to grind the points and notch the rails. I discovered a hand file is just not going to cut it.

For ties, I have switched to cedar strips I cut from those cedar planks they sell to cook fish on. There are other sources of cedar which would probably work better in the long run but I can get these planks at several local grocery stores so I have been using them. You will need some sort of table saw to rip them into strips, I use a cheap little rockwell saw I got from Lowes for $100. Soak these ties in stain for a couple of days too. Outside weather is a real killer of wood without lots of protection.

Another tip I found is use real model rail spikes. At first, I made mine from small brads and they do work but the spikes are way way easier to use and look and hold much better.

I get my rail from https://llagascreekrailways.com/

You can find spikes here – Spikes

For the switch throw, there are various ones on the market, I use waterproof servos and a magnetic clutch for mine.

Building

This is the tough part. You have to measure all of the rail and carefully bend it to the proper shapes. The points have to be ground down on the bench grinder (be careful with this thing, it can hurt you).

This is where the flip side of the board comes into play- an exact duplicate of the pattern so you can just flip the board over, measure/fit/grind the rails and then turn it back over and spike them into place. Note in the pic at the top I have used rail clamps to join three small pieces of track to insure the gauge. I also have a couple of plastic and metal wheel trucks that I hand run over the switch to make sure everything lines up and operates smoothly as I spike the rails into place.

One thing that I neglected with my first turnouts- if you are going to operate outside, do not skimp on the ties, use cedar and soak it in oil type stain.