As we enter 2014, I thought I would post up a recap of what I’m working on. Primarily I’m developing a wireless method for controlling moving vehicles. In my particular case, this is Garden Scale (G) model train locomotives. However the principles and widgets I’m designing could be used to drive almost anything via real time wireless up to a distance of about 300 ft (100 meters).

The key difference between my method and say standard FHSS (or similar) 2.4Ghz Radio Control is that I am oriented toward a computer driven network, in my case, 802.15.4 as implemented with the Xbee Series 1 modules.

Why a computer network? Well, for one, it gives me fine control over the exact data I’m passing back and forth. Second, it’s bi-directional. The network is oriented as a single to many so any device can talk to any other device. Each Xbee module has a unique 16 bit ‘node address’. You just form a message, add the address of the node you want it to go to and send. The network takes care of getting it there.

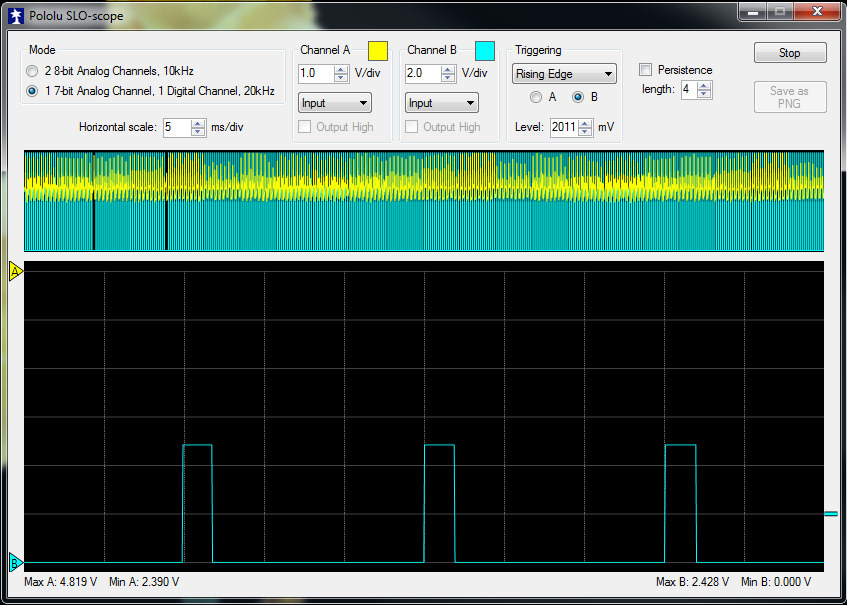

This is quite powerful. You can be sending control data to your locomotive and then, as it passes over an RFID tag, it could send that position data back to the computer (or your hand-held, or another device, etc) in real time. Additionally, other data such as speed, current draw, etc could be returned from the locomotive as well. Just because this is a computer type network, it isn’t slow. I’m getting data packet transmission times in the 7ms range which is quite fast. (For reference, your average servo scan time is 20ms)

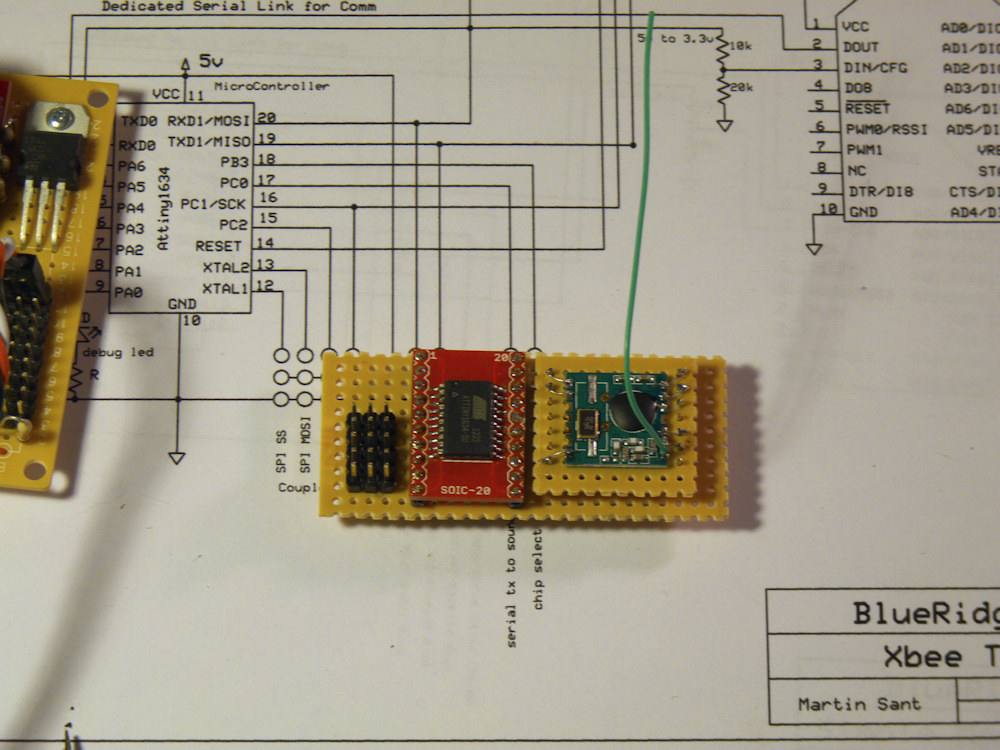

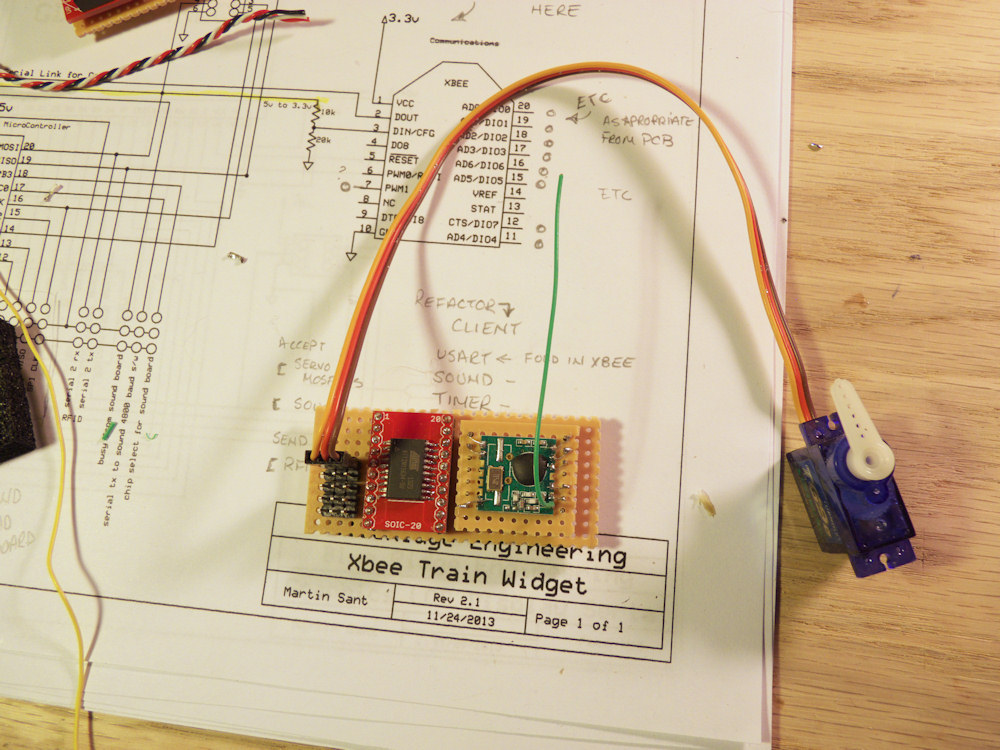

Anyhow this level of potential automation is, by electronic design standards, fairly simple. I have an Xbee and an Attiny 1634 Microcontroller as the main components of my ‘Train Widget’ and that’s pretty much it. Basically about $22 worth of electronics as the ‘brain’ of all of my devices.

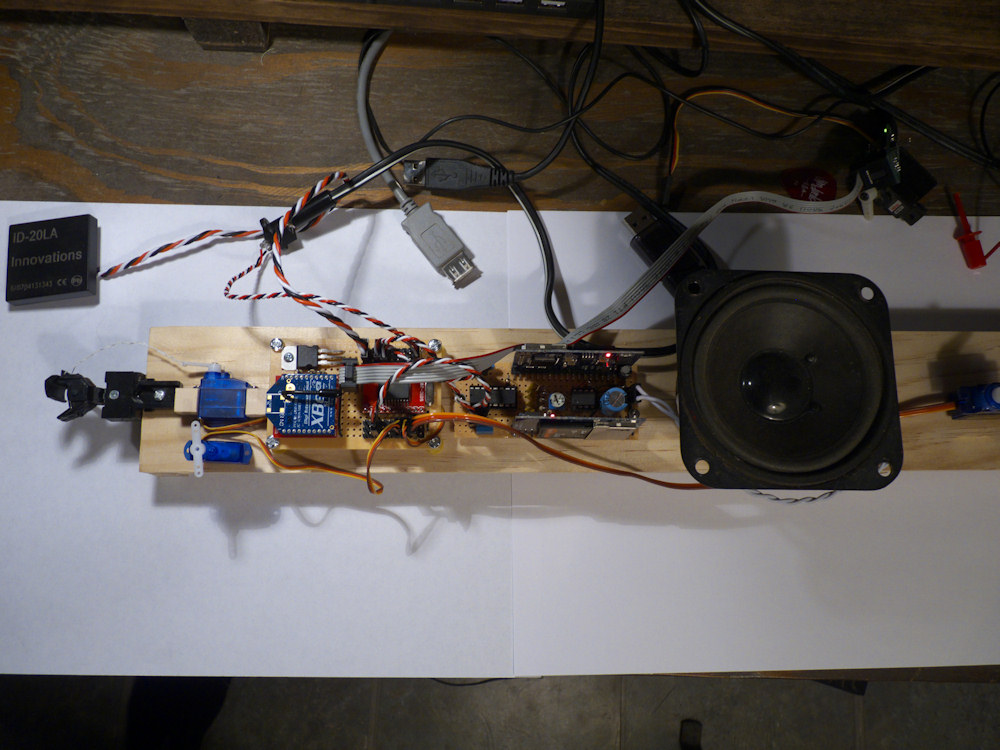

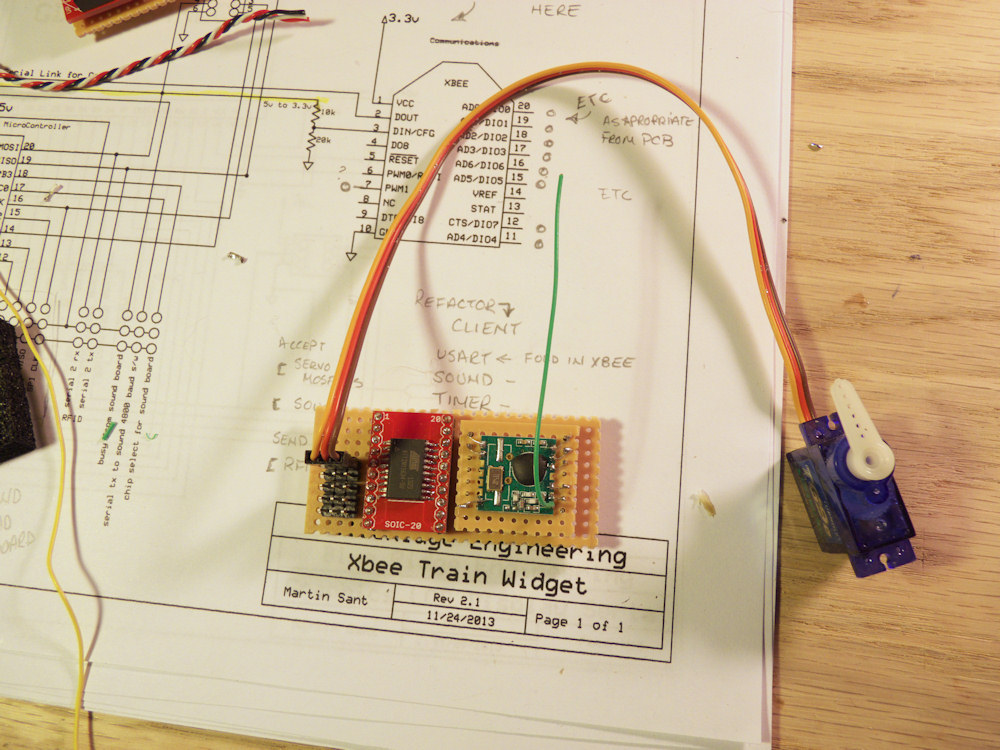

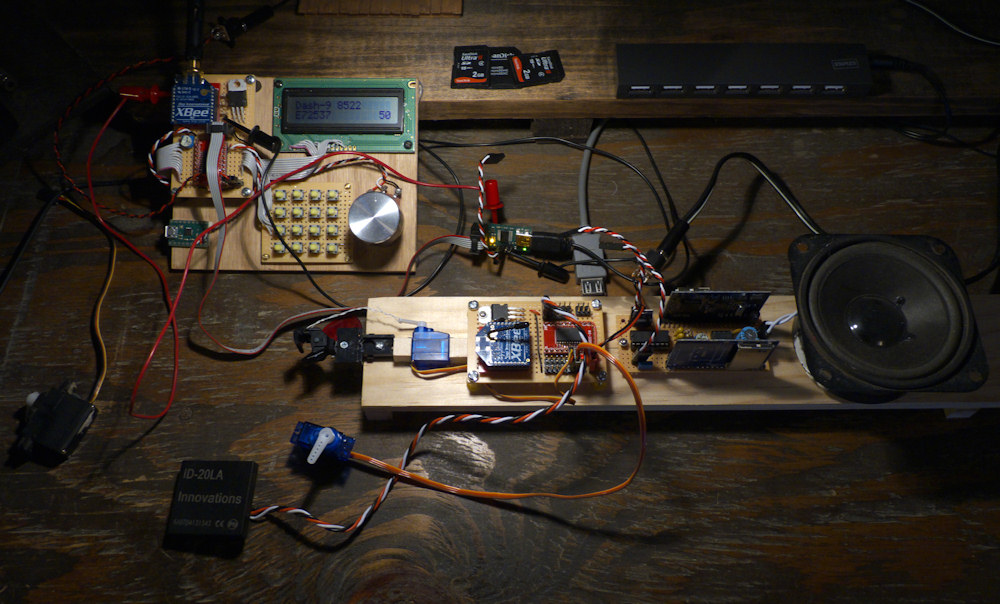

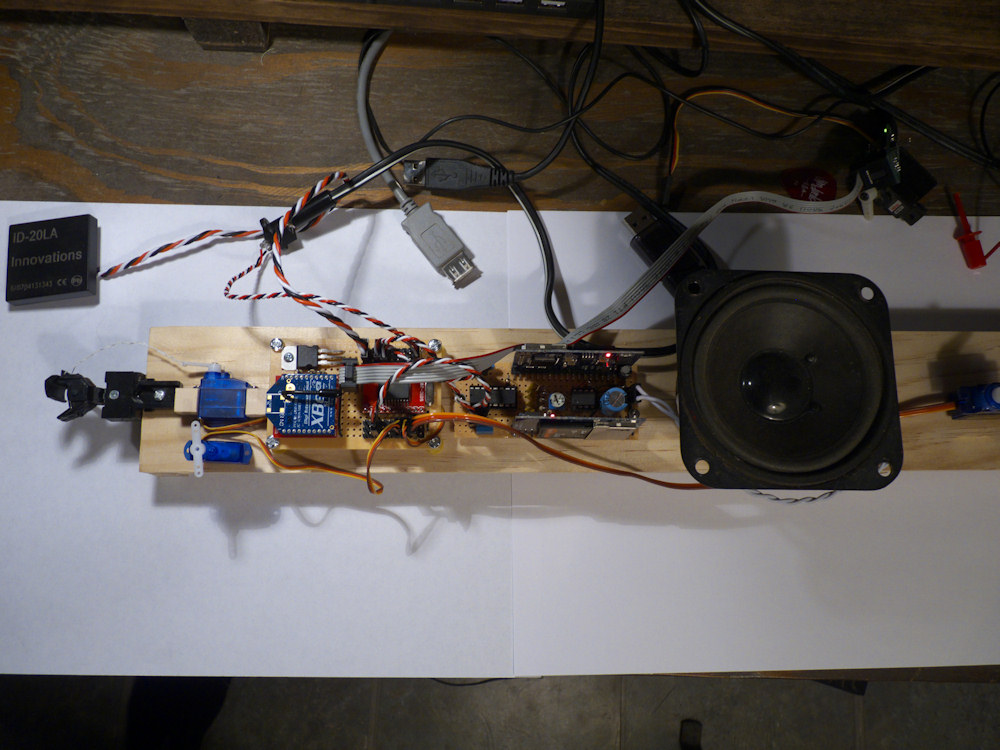

This is a picture of the basic train widget. Xbee does the communications, the Attiny handles the processing and drives the servos and motor controller. It also sequences the mp3 players (2 stereo channels) so you can play sounds via commands sent over the network or by throttle control positions. The two cards are just to the left of the speaker which I’m driving with a generic LM386 amplifier chip and some caps from Radio Shack.

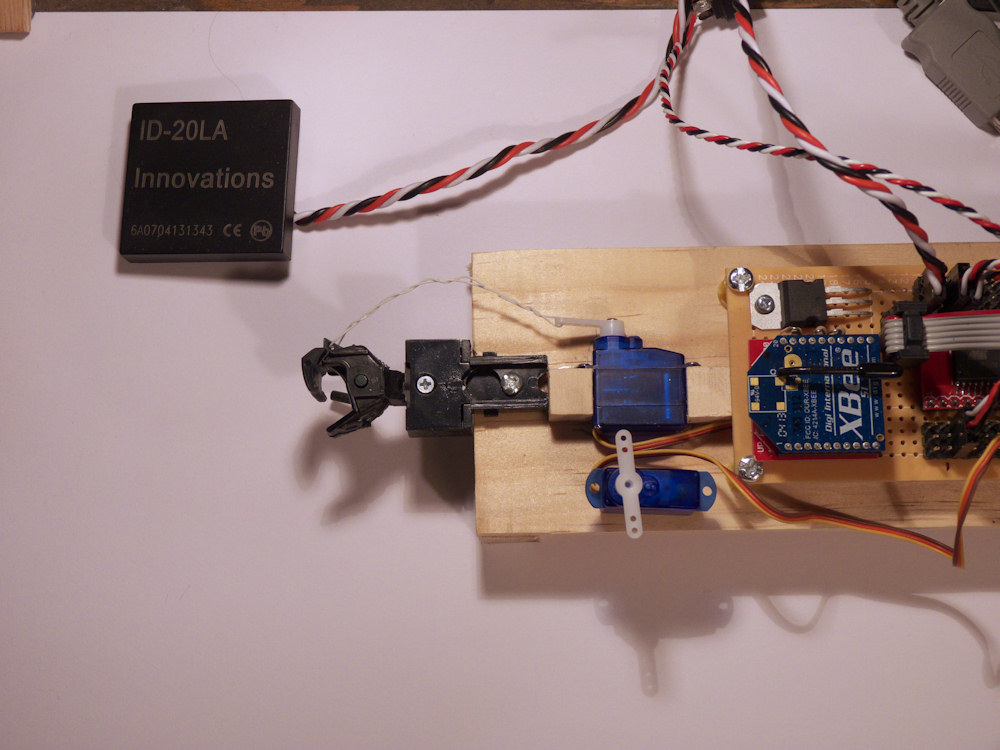

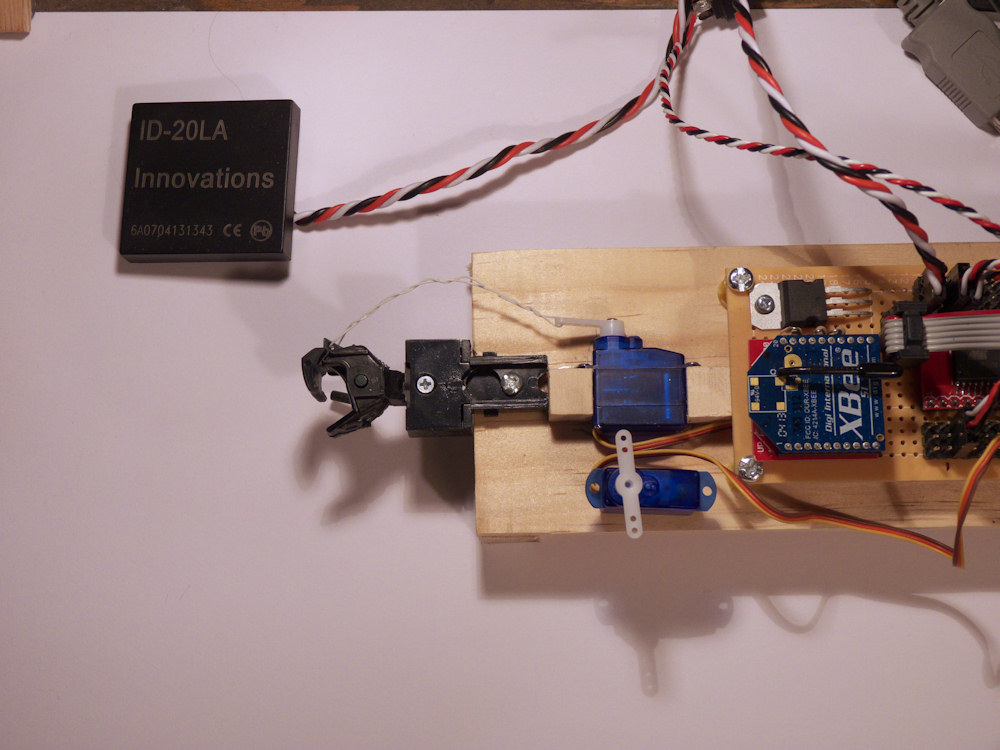

Above is a shot of the front end showing the coupler connected to a micro servo, the ‘back’ coupler servo sitting beside it and the RFID reader in the upper left. I have all of this working including the transmission of the RFID data to the hand-held.

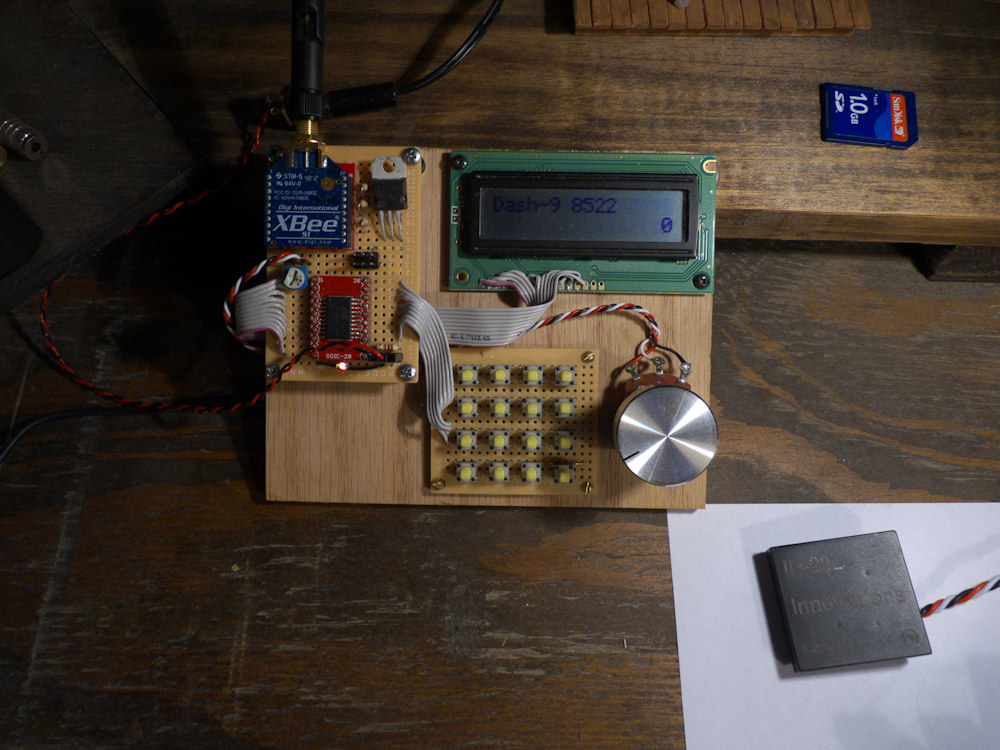

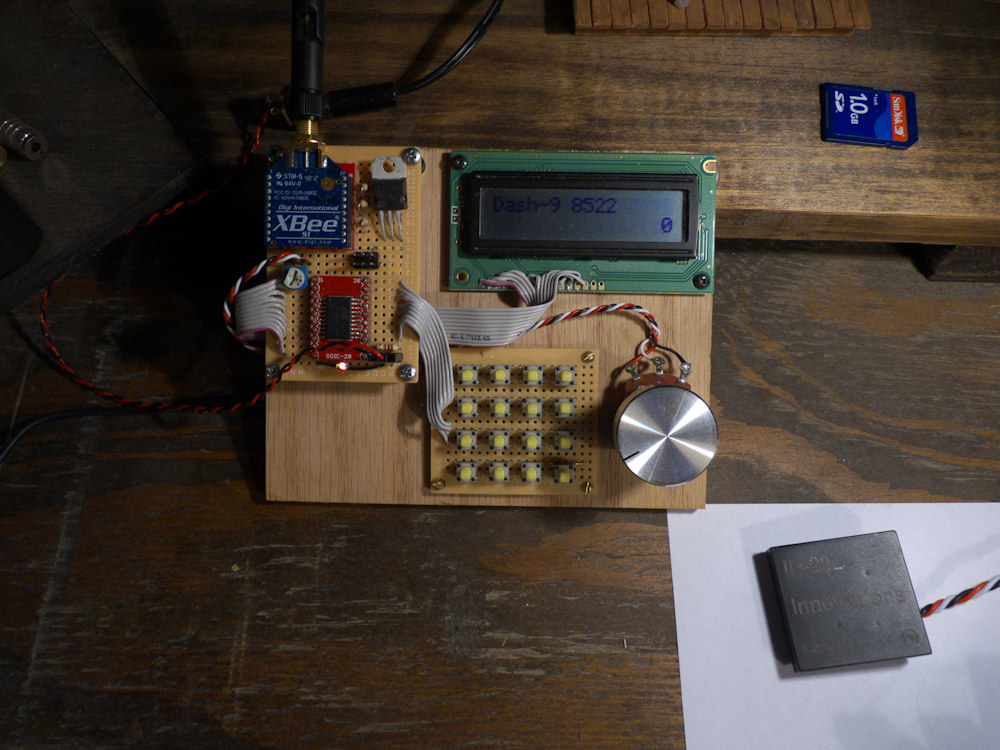

This is a picture of my stand alone ‘simple’ hand held throttle prototype. I also have all of this working, however only at a basic level of controlling one locomotive at a time, I don’t have any multiple unit code in there yet. I’m also thinking of going with a graphic display instead of this ASCII only one and also designing a ‘cradle’ or appliance of some sort so I can use my tablet as a user interface instead of a LCD. (See the post below this one)

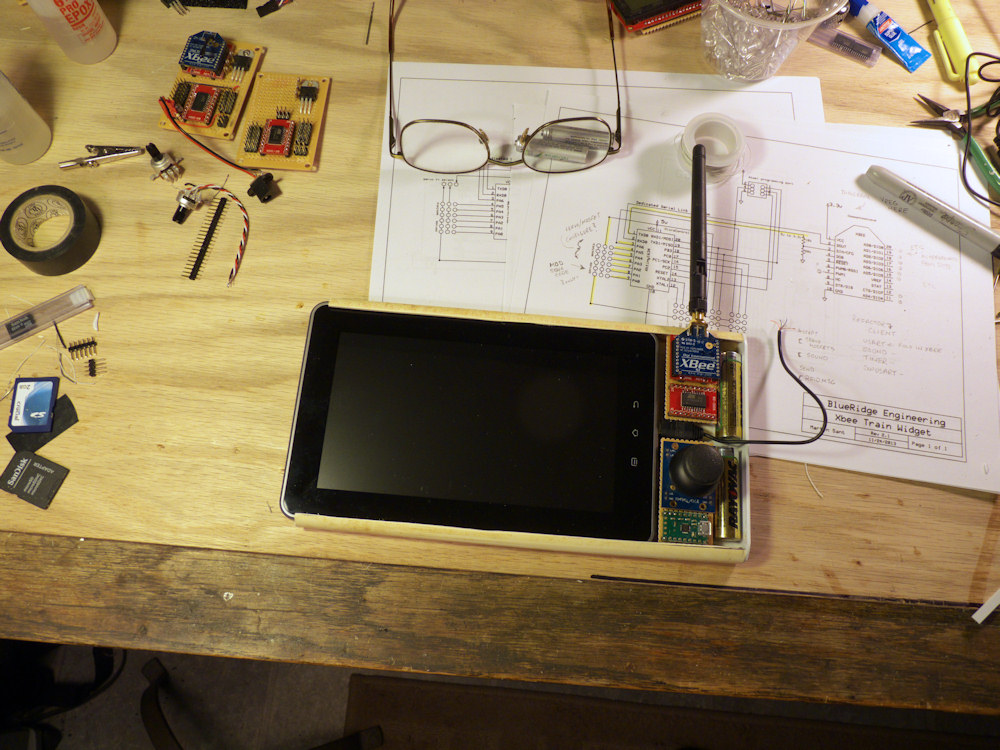

Finally, this is a pic of my uncoupler device. One of these per car with the locomotive in charge of each one. The handheld would allow you to address the locomotive and then each car individually to uncouple anywhere. Each of these consist of one Attiny Microcontroller and a small 2.4Ghz transceiver. The locomotive has the ‘master’ transceiver and can talk to each car in the train that has a ‘slave’. The Attiny then controls the servo motor to move the coupler. This is clocking in at about $2 for the Attiny and $8 for the transceiver. Add $4 for a servo. Not super cheap but not too bad. $18 per car? I guess. Hmm, need batteries too…