All finished up, new engine, new paint, new interior plastic, new carpet! Only thing left is new windows, that’s next.

Some pics from many years ago, Zack loved to fly, he had his own headset.

Used up an entire quart of white single stage auto paint. Missed a few spots, but it came out well and gave it a nice fresh look.

Still working on my outdoor layout, it got pretty smashed last Jan with all the snow and downed trees. Most of the major construction is done, just one or two more concrete mountain touchup work. Got a nice loop of track done so the train can make it all the way around finally. Still have some sidings and more track to lay down but it’s getting there. Perhaps by fall? But it is almost fall so hmm.

Finally shelled out a few dollars and got a brand new rig.

Intel Core i5-11600KF @ 3.90GHz 3.91 GHz

Installed RAM 16.0 GB

GEForce RTX 3060

Really nice box. Runs Unreal Engine 5 great but it turns the computer into a space heater when it does.

Engine finally got to the end of it’s life (2300hrs, a good run) so while it’s off getting overhauled, I figured I would spruce up the old bird with some fresh paint. Nothing spectacular, same basic design, just putting on a fresh coat. Got some single stage auto paint and a paint gun, having lots of fun (well, fun is a relative term here) but it looks good so far. Already hit the cowl, it came out pretty good. Got her all taped up and ready for a nice coat of white.

Riley and Sophie, Riley is the black one, about 8 months old now. Molly is the old lady, she is just about 10 but still pretty spry.

The newest addition to the clan, Riley. Male German Shepherd. Black paint job with matching trim and upholstery. Quite the character already at 3 months old. We have two females so Zack’s passing left a power vacuum in the pack. He seems to be a good candidate for the alpha position. Very smart little fellow but he talks back a lot. I think that is a plus on his resume though. ha.

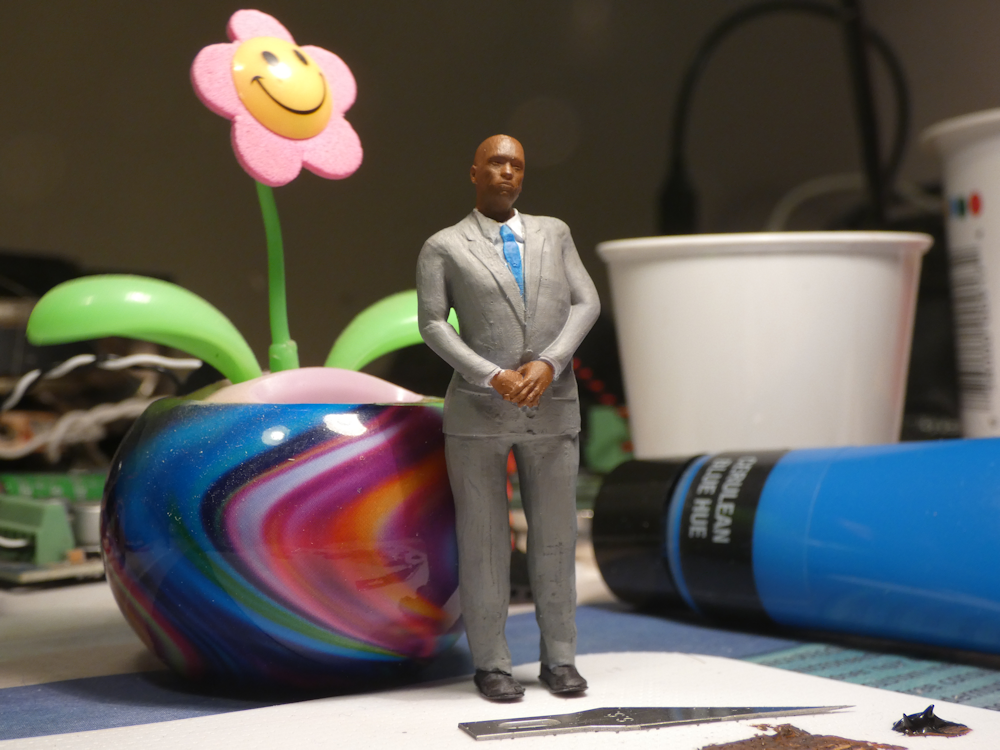

I’m finally getting the hang of my new 3D printer, a Creality Halot One Resin printer. Resin is a bit messy but not too bad and doesn’t smell near as bad as everyone lets on in the Youtube videos. In fact, with the top on, it’s barely noticeable. Anyhow, here is my preacher man, intended for the Country Church I made earlier this year. He is painted with acrylic with just a tad of dish soap mixed in to thin the paint. For some reason, that makes the paint stick really well, I don’t need a primer on these. Anyhow, I am working on more folks for his ‘flock’. This guy (and his future parishioners) were (will be) made with MakeHuman and and then edited in Blender. Blender 3.0 is quite powerful, I wonder how it remains free. Lots of new features and refinements with the 3.0 release, lots of fun when you have to stay inside all the time because of the weather.

Finally finished up my Country Church. This is modeled after the one on Profit Road in Charlottesville and in real life sits near the Norfolk Southern Washington Division Track. The basic structure is styrene sheet cut out on my table top CNC machine with lots of details printed on my Creality Ender3 FDM printer. It thought it came out pretty good. It’s just sitting here at the moment, it will get a permanent place on the layout this spring. Dogzilla there keeps an eye out for squirrels.

Latest locomotive rebuild. USA Trains S4 Switcher. Completely disassembled, stripped and repainted. Threw out all the original electronics, replaced all bulbs with LEDs and installed a TSU4400 5Amp decoder. A Cytron 13A motor driver supplies DCC controlled by my Protothrottle Xbee Receiver. A Visaton full range speaker provides the sounds. I think it came out pretty well, some of the painted letters are a bit rough but for the most part I’m pretty happy with it.