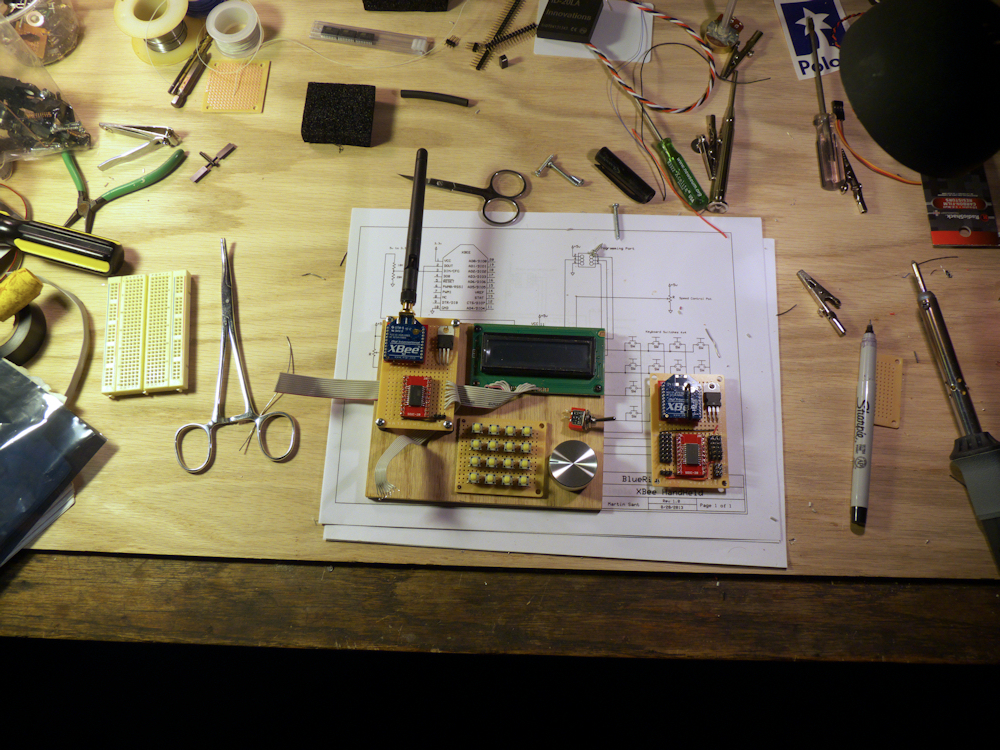

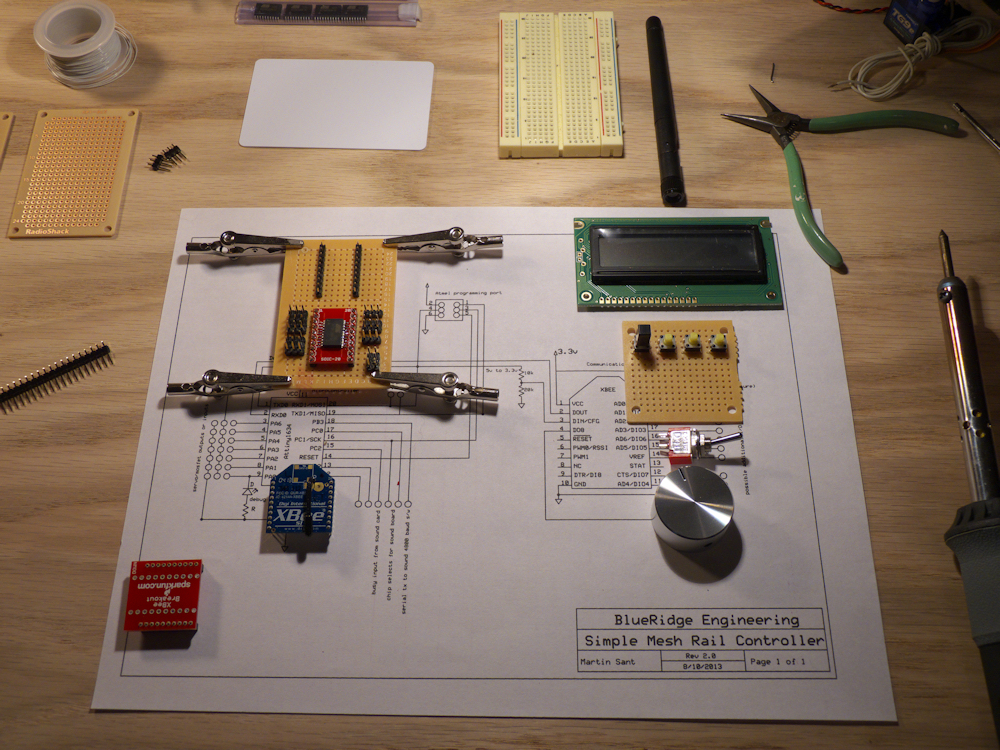

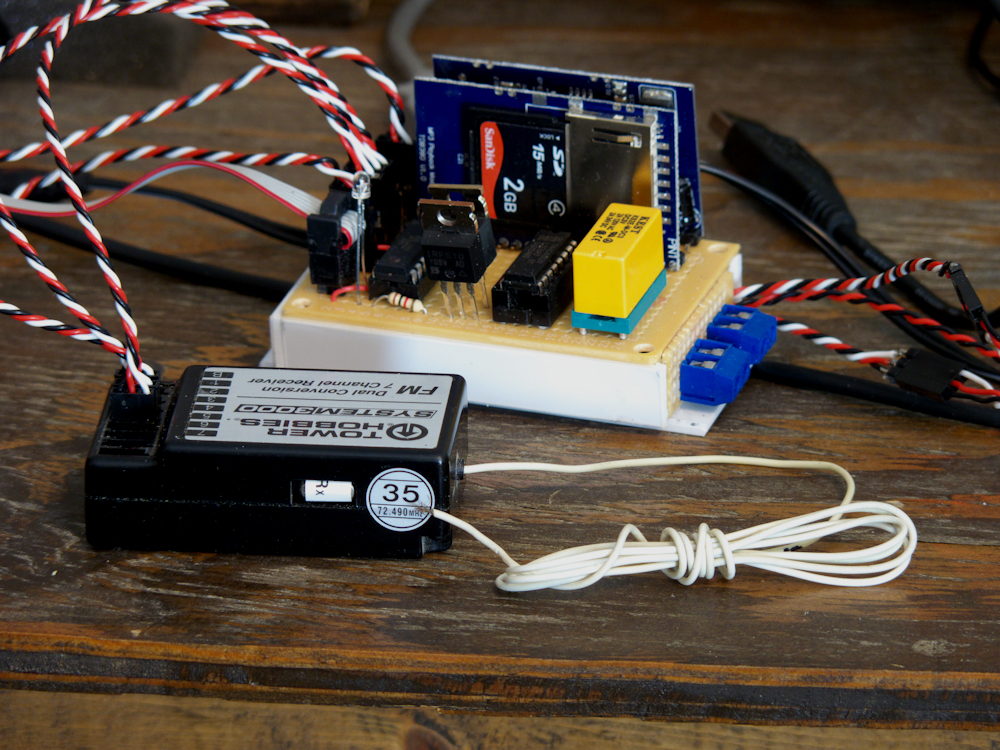

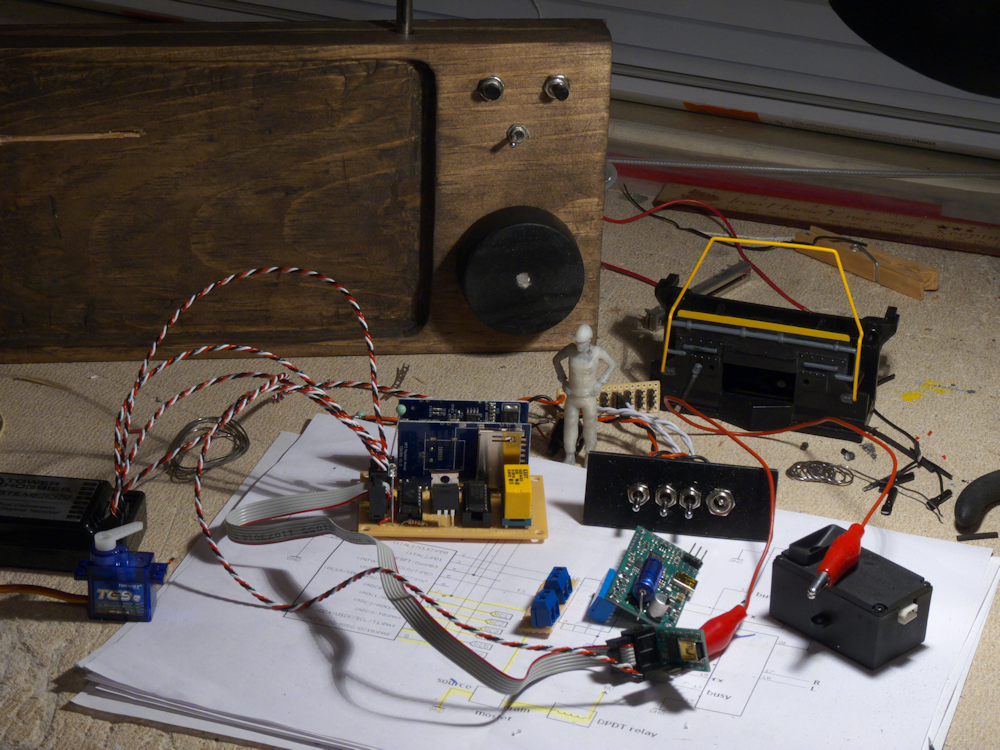

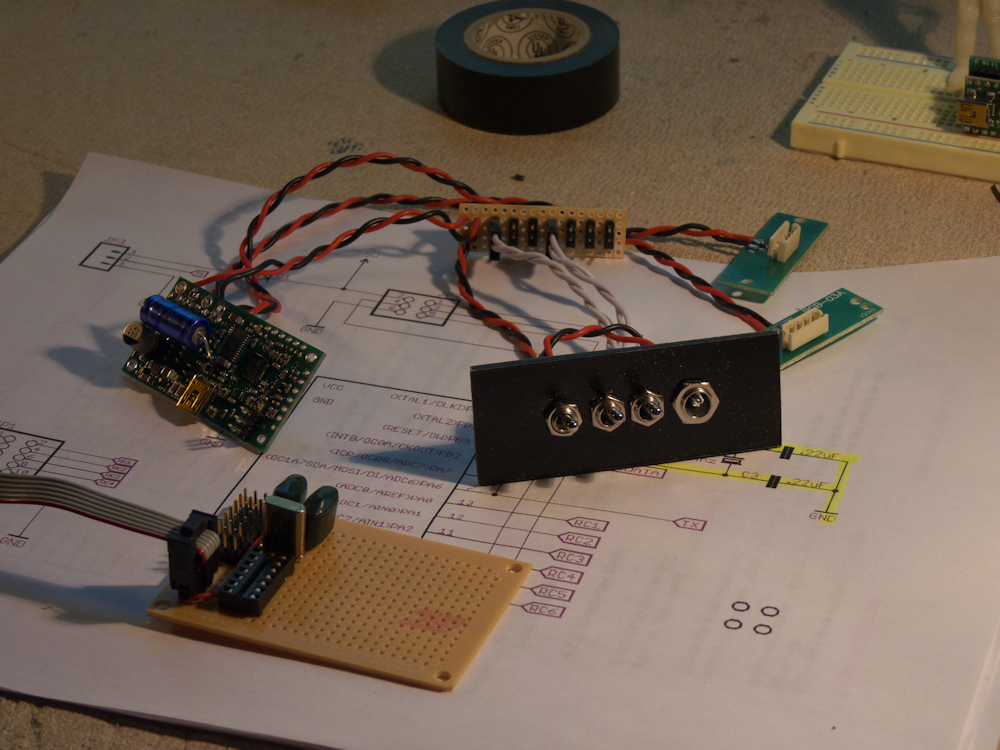

More work on my prototypes. I have most of the boiler plate soldering done on the breadboards, the ground and power is all done for both. Signal paths are not, I plan to wire-wrap those. For the hand-held, I have a reasonable parts layout so that I can actually use this thing. I’m going to have to lay all this out on a PCB before I can design the actual hand-held enclosure but for now this will let me do all my development.

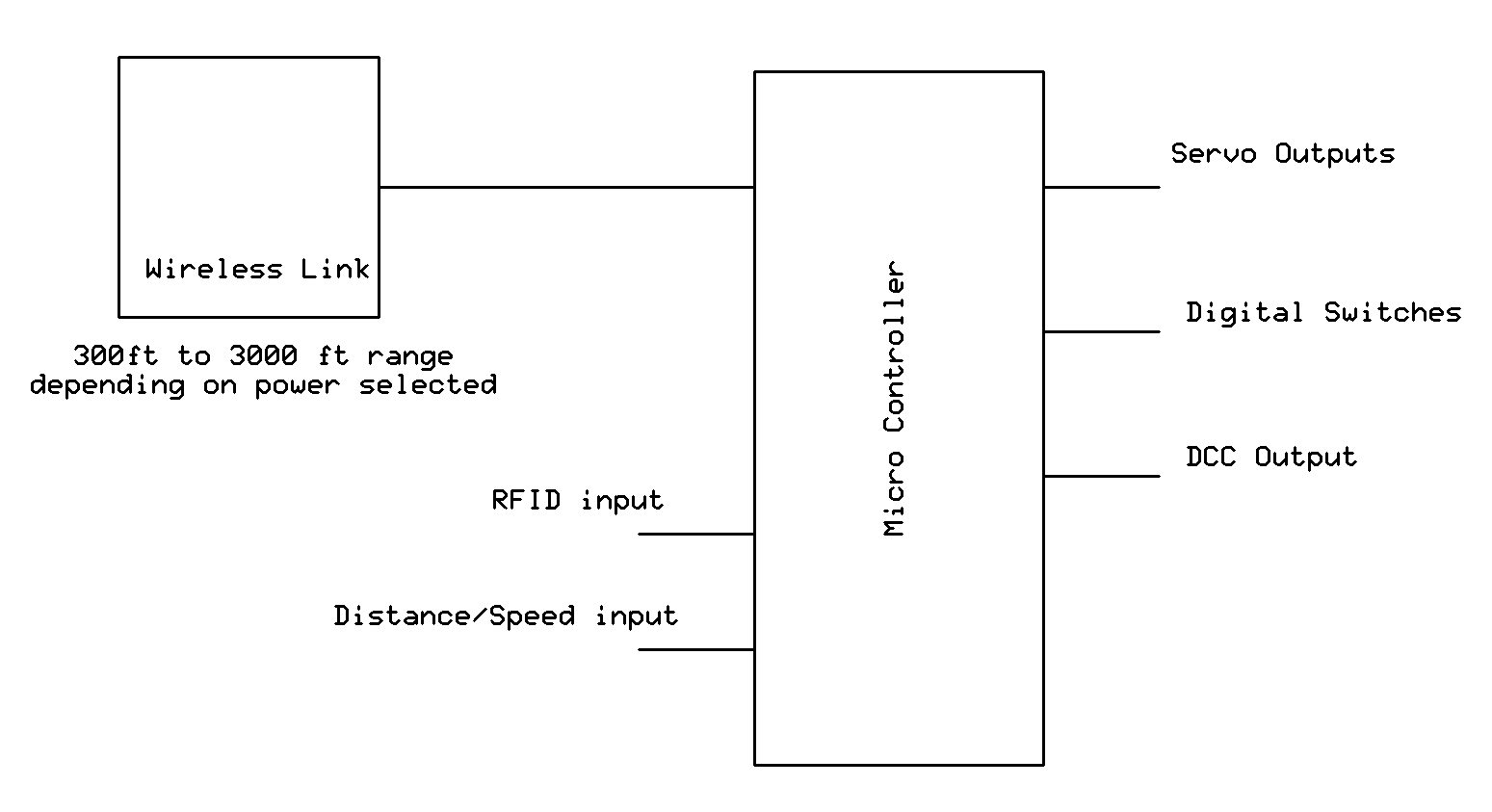

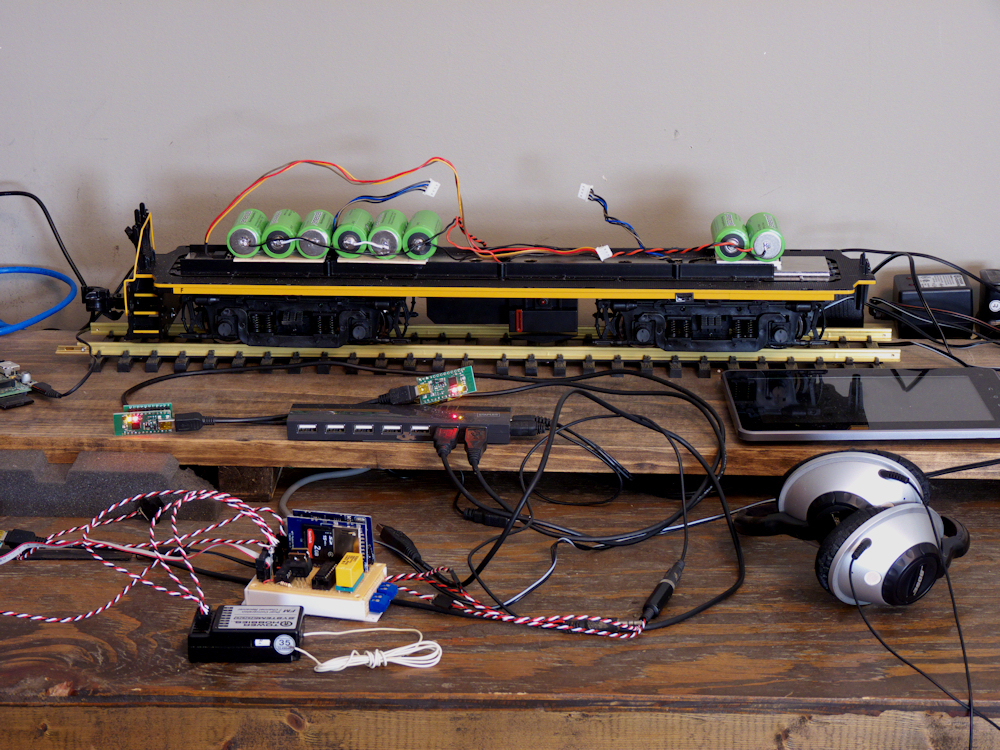

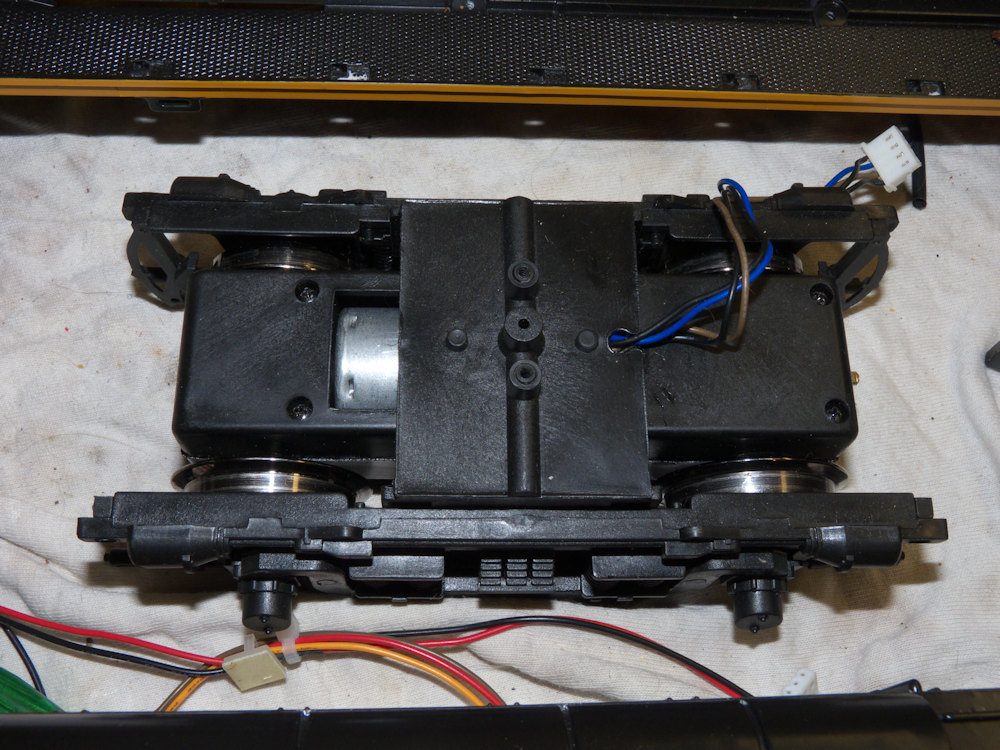

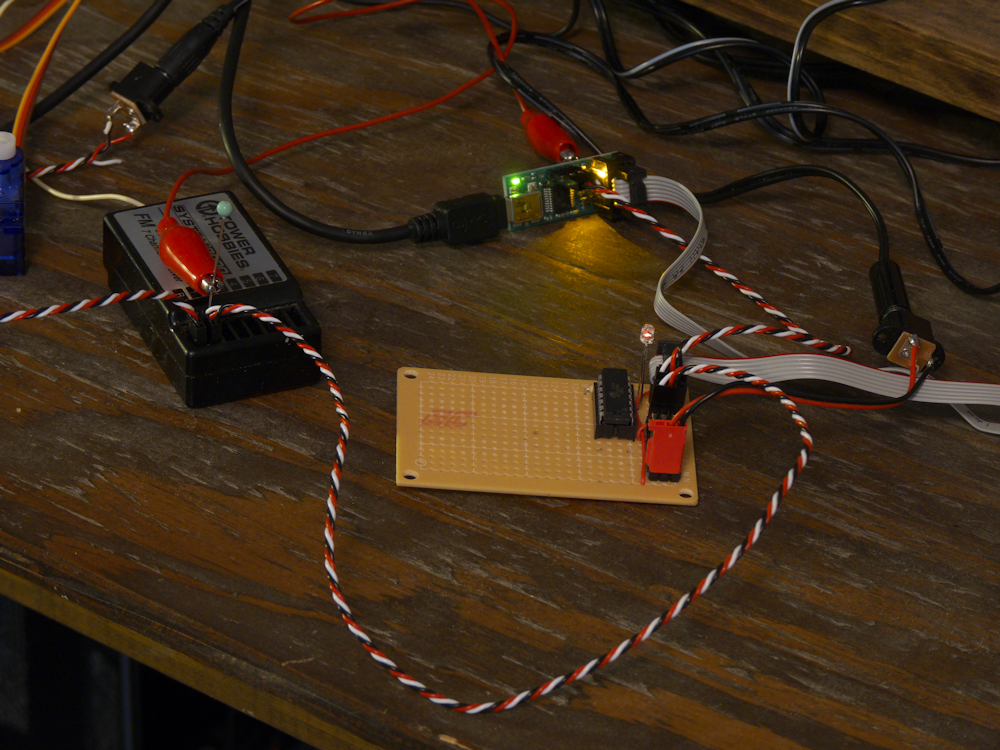

The ‘slave’ node on the right is super simple. Xbee and a micro-controller. All the work will be in the code. I’m planning 3 servo outputs, 5 mosfet digital outputs, a serial out for a two/four channel sound card and a serial input for the RFID transponder. If I can get the DCC protocol figured out and coded I’m going to put that in there as well. All this will leave one pin free for a possible distance/speed sensor. Anyhow, it should be a good development platform.

I guess it’s a bit of a misnomer to call these Master and Slave. While I’m going to start off with that, the idea is to eventually flash the Xbee modules with the digimesh firmware. This will make these just two equal nodes on the network. In this case, a hand-held control unit node and a locomotive (or whatever) node. Not shown yet (because I haven’t started on it, duh) is the computer node that will plug into my Raspberry Pi and offer sensing and control over the whole net. Or that’s the plan…