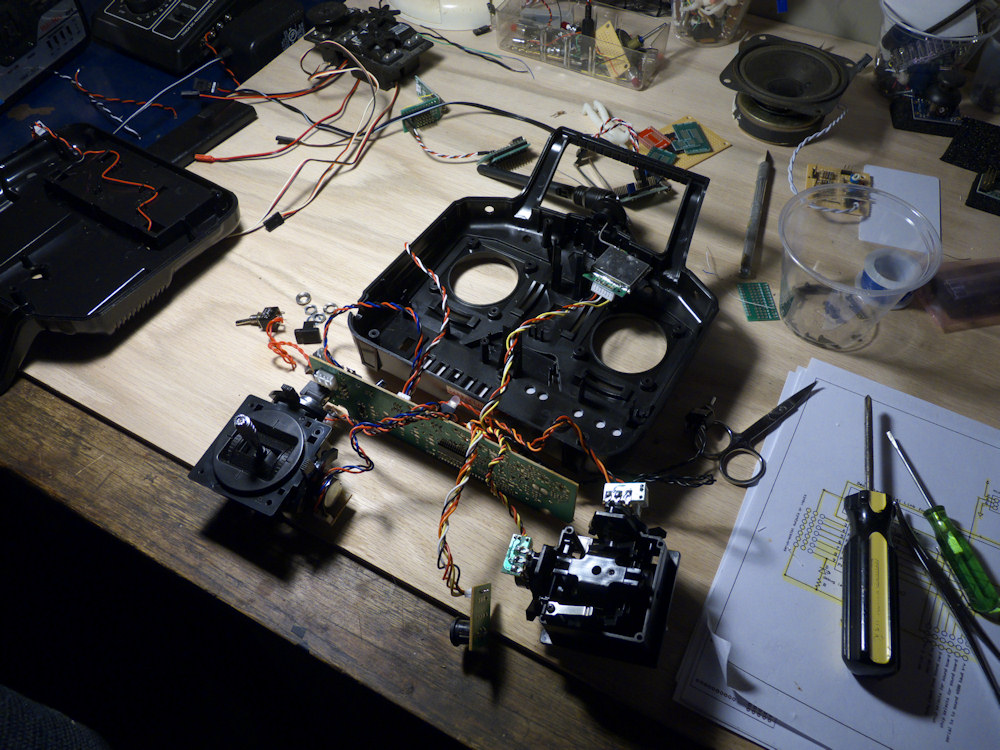

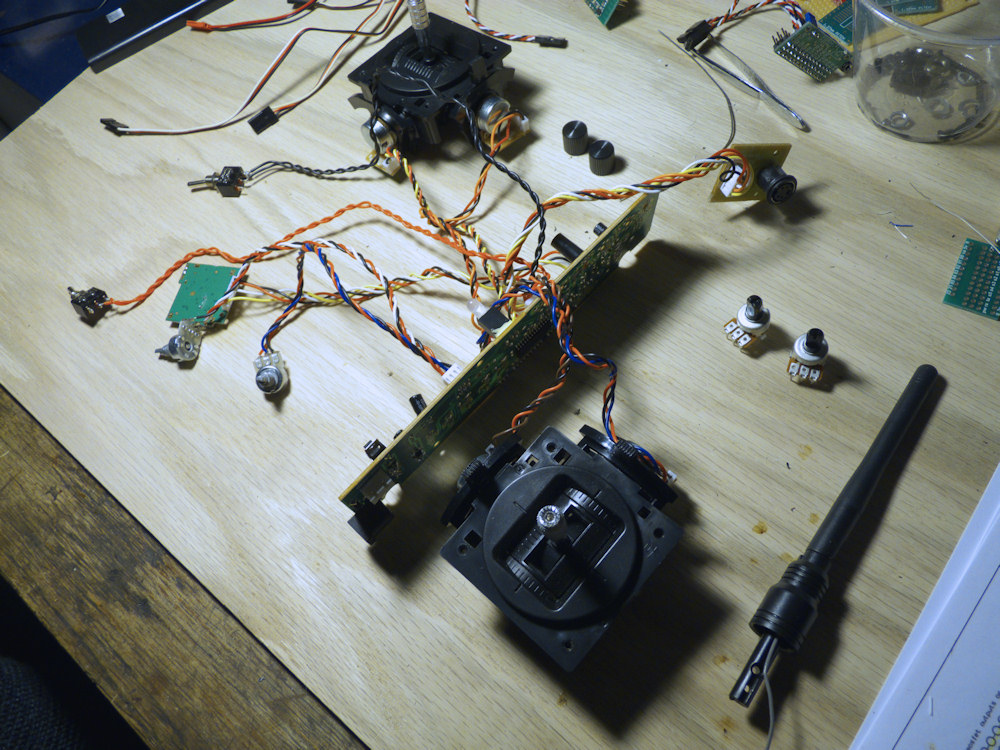

Spent most of the Holiday weekend finishing up the soldering on my various train widgets.

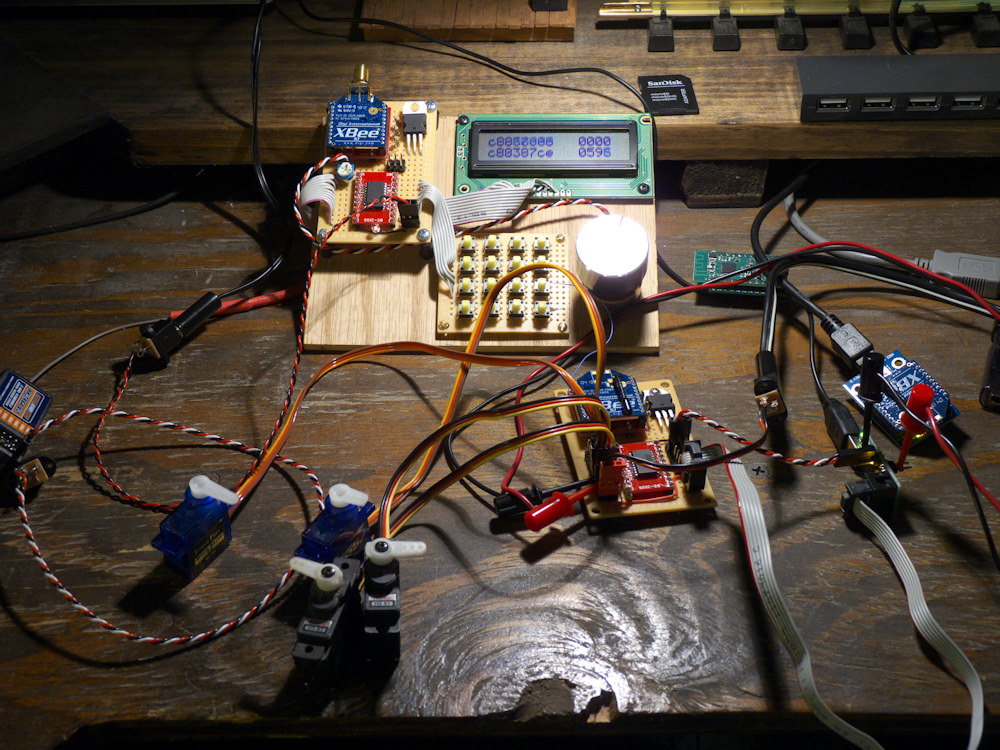

On the left is the Pololu 18v7 7 amp DC motor controller. This is a commercial board. It works great in my Aristo RS3 and allows bi-directional control without a reversing switch. It’s very configurable. You can run it bi-directional or single direction and it has configuration items for acceleration and braking although I have not tried those yet.

To the right of that is my ‘helper r/c’ design. This board reads r/c channels and converts the servo pulses to flip a relay (for reverse) and turn on up to three MOSFETs (for lights) using standard R/C airplane sorts of radios (one channel per). I noticed some people who use cheaper airplane ESCs are dedicating a servo to flipping a toggle switch onboard the locomotive, this eliminates that. (Personally, I like having a reverse switch so I configure my Pololu that way anyhow). This is a very inexpensive board based on the ATTiny84 micro-controller.

Not shown is an R/C sound board, it allows you to play any mp3 sound, triggered by a channel on the radio. Stick all the way to the left, play sound 1, all the way to the right, trigger sound 2, in the middle, silence. So horns, bells, or music even if you are so inclined. I’m thinking 1-4 channels of sound depending but I have not finalized that yet.

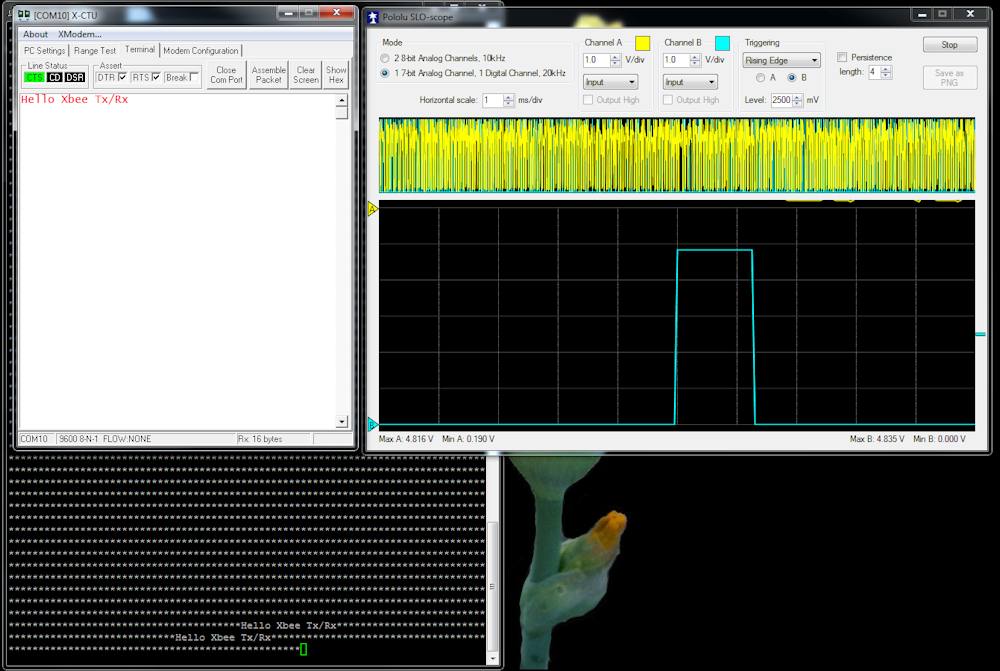

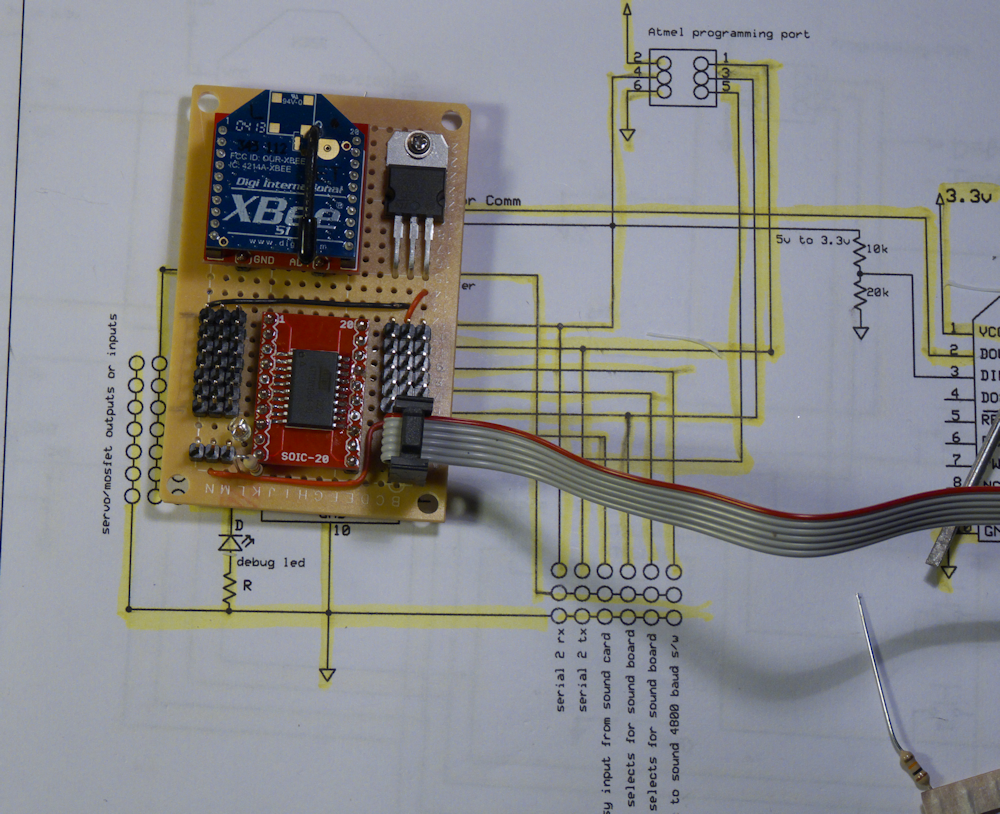

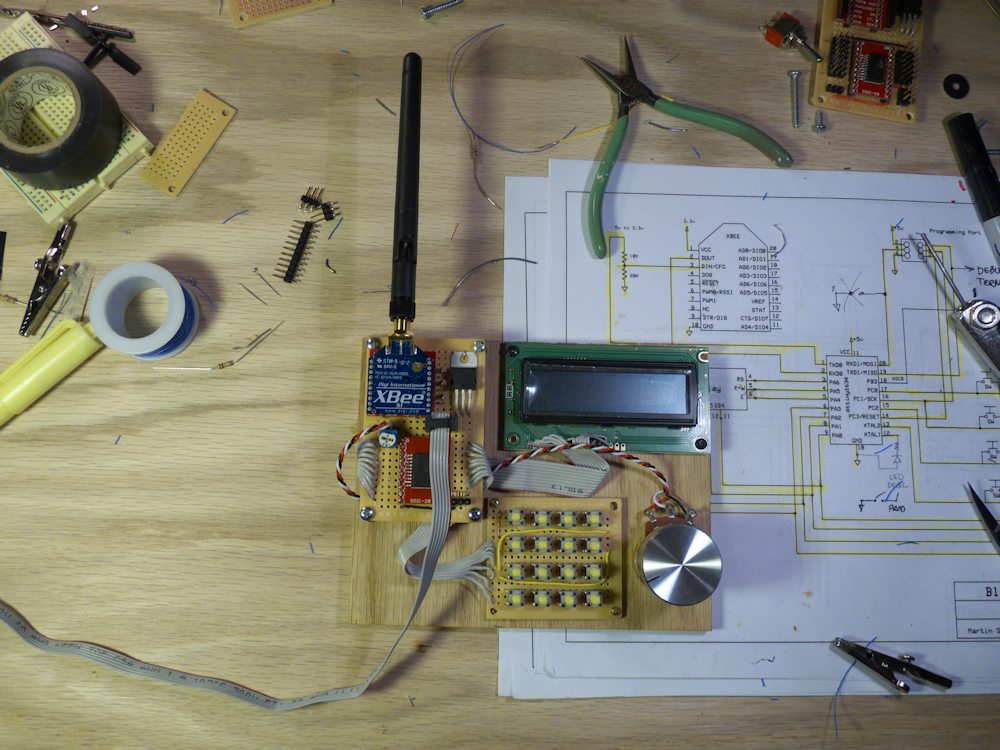

Next on the left, below the motor controller is my Xbee widget. This is going to be the basis of all of my new wireless designs. I can re-use the basice design and populate the board with different s/w only, no need to change the h/w to have several different ‘widgets’.

Depending on the s/w, I’ll be able to control servos, DC motor controllers, MOSFETS (on/off power switches) and drive my 4 channel mp3 sound card. I’d also like to provide the option of DCC outputs to feed various decoders but that s/w hasn’t been developed yet.

It will also provide serial inputs for things like RFID readers, speed and distance counters, current sensors and other things like that. Note that this doesn’t have to be a locomotive unit, this node could go anywhere to control turnouts or animatronics, etc.

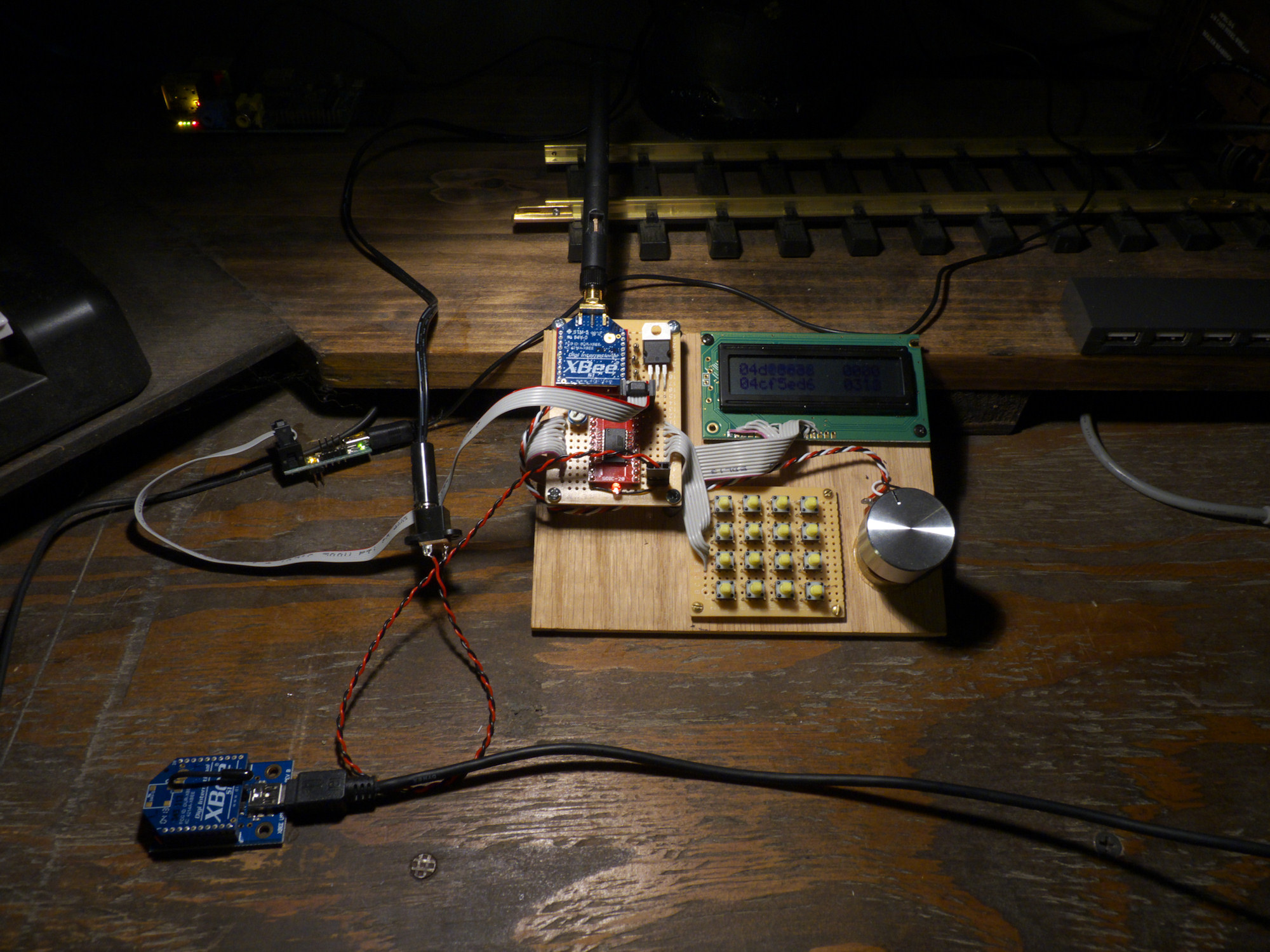

With another set of firmware, it will act as a hand-held controller. A rather large prototype of that is in the center of the picture. (This should fit down into a nice sized handheld unit once it’s put on a PCB)

Yet another incarnation of s/w will produce a widget that will interface to your computer, allowing control of any other widget.

The radio for the wireless is the Xbee series 1. These are low cost radio nodes, come ALREADY FCC certified and have a range of 300ft. They also provide a set of firmware called digimesh that turns your network of nodes into a self-healing mesh network. VERY COOL. The proctocol is also open source so no more proprietary radio communications! Love that.